2 月 . 18, 2025 12:36 Back to list

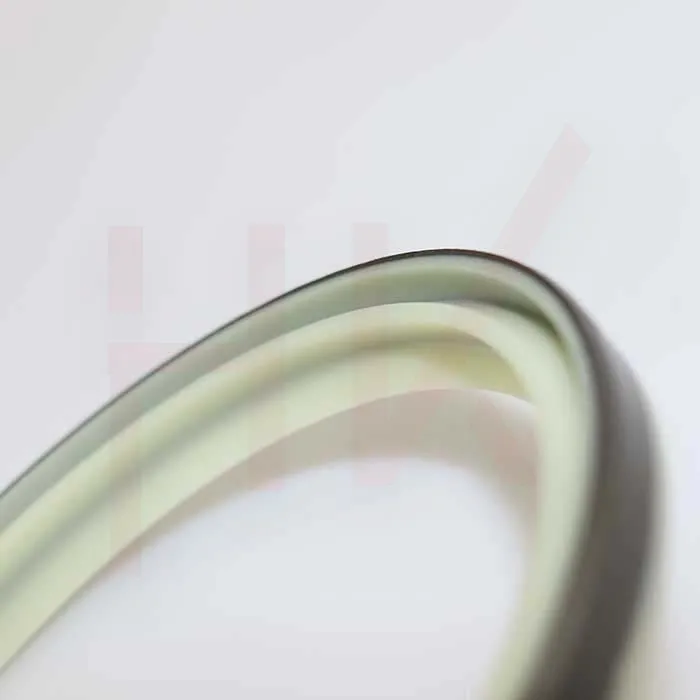

170×190×13 Tcv Oil Seal High Pressure Oil Seal Hydraulic Pump Seal

From an authoritative perspective, the continuous innovations in seal kit technology underline their importance in extending the lifecycle of hydraulic systems. Advanced manufacturing techniques improve the durability of these kits, integrating features that mitigate common issues such as friction and heat expansion. Furthermore, industry standards and certifications serve to reassure consumers of the reliability and safety offered by top-grade hydraulic pump seal kits. Trust in hydraulic pump seal kits is built through persistent performance in demanding conditions. Testimonials from industry professionals frequently cite the drastic reduction in system failures and maintenance times after installing quality seal kits. This credibility stems from the consistent operational improvements that these components deliver. Incorporating a hydraulic pump seal kit is not merely a maintenance consideration but a strategic decision that impacts operational efficiency. It is a smart investment for any industry reliant on hydraulic systems. Understanding the pivotal role that these seals play, supported by the latest advancements in technology, positions businesses to gain a competitive edge, securing both the longevity and performance of their machinery. In conclusion, maximizing the capabilities of your hydraulic systems means never overlooking the significance of a hydraulic pump seal kit. Whether you are an engineer, a procurement officer, or a business owner, understanding the intricacies of these kits and making informed choices backed by expertise, trustworthiness, and reliability can make a significant difference in your operations. By emphasizing these factors, industries can significantly enhance productivity while ensuring long-term cost efficiency.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories