2 月 . 12, 2025 01:57 Back to list

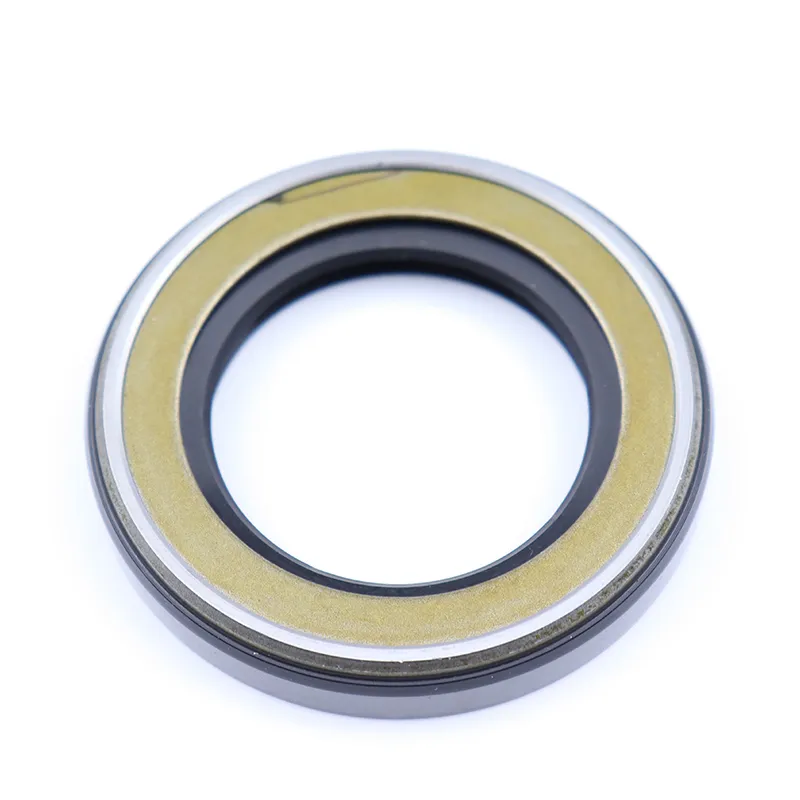

oil pump seal

The expert selection of a hydraulic pump seal kit aligns closely with understanding the specific requirements of the machinery in question. Key considerations include operating pressure, temperature range, fluid compatibility, and environmental conditions. Each of these factors demands a tailored approach, informed by a detailed study of the manufacturer’s specifications and field conditions. Engaging with industry experts and leveraging resources such as engineering forums can provide invaluable insights, leading to informed purchasing decisions and optimal equipment performance. Authority in the realm of hydraulic systems is often built on established industry standards and compliance. Reputable manufacturers of hydraulic pump seal kits ensure their products meet or exceed these standards, providing users with the assurance of quality and reliability. Partnering with such manufacturers affords access to certified products, bolstered by robust technical support and warranties. This relationship amplifies the trustworthiness of the equipment and its ongoing maintenance, mitigating the risks associated with system failures. Trust, as the cornerstone of customer satisfaction, is best cultivated through transparency and accountability. Providing detailed product data sheets, user testimonials, and case studies exemplifies a commitment to customer education and service excellence. A trusted provider not only furnishes high-quality products but also equips users with the knowledge to effectively install and maintain their hydraulic systems, fostering a long-term partnership founded on mutual respect and benefit. In conclusion, a hydraulic pump seal kit is not merely a collection of components; it is the foundation of hydraulic system integrity and performance. Understanding the nuances of these kits from experience, expertise, authority, and trustworthiness perspectives underscores their undeniable value. By prioritizing quality and aligning with knowledgeable partners, users can ensure their hydraulic systems operate at peak efficiency, safeguarding their investments and optimizing their operational capabilities.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories