9 月 . 23, 2024 02:26 Back to list

hydraulic press seal kit

Understanding Hydraulic Press Seal Kits A Comprehensive Guide

Hydraulic press machines play a pivotal role in various industries, including manufacturing, automotive, and metalworking. At the heart of these powerful machines lies a critical component the seal. The hydraulic press seal kit is essential for ensuring the efficient and safe operation of hydraulic systems. In this article, we will explore the significance of seal kits, their components, and some tips for maintaining them.

What is a Hydraulic Press Seal Kit?

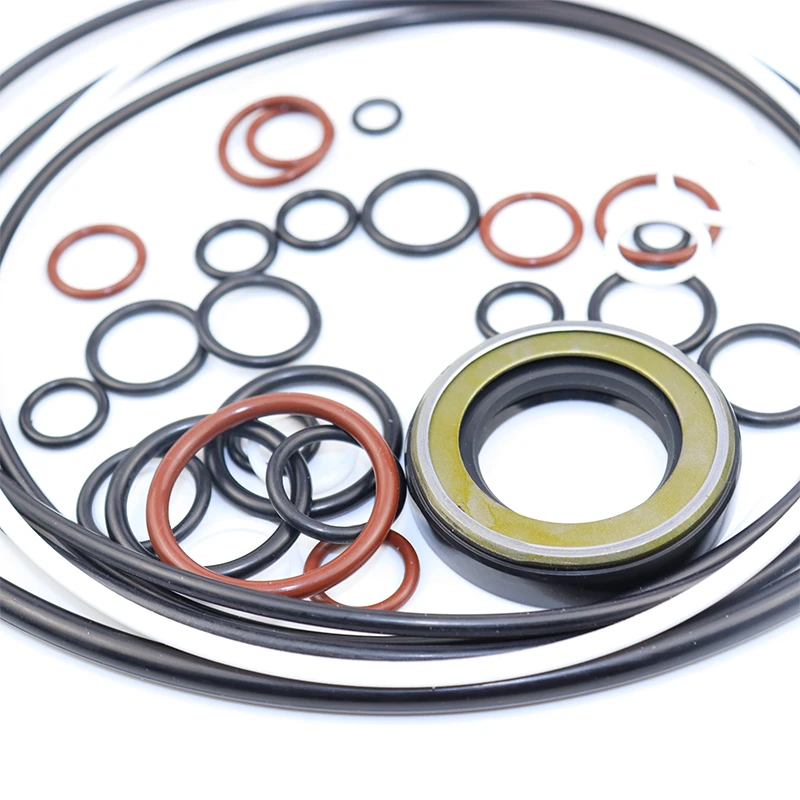

A hydraulic press seal kit consists of various seals and gaskets designed to prevent fluid leakage and maintain pressure within the hydraulic system. These kits are specifically engineered to withstand the high pressures and temperatures associated with hydraulic operations. A typical hydraulic press seal kit includes O-rings, piston seals, fluid seals, and backup rings, each serving a unique purpose in the overall functionality of the hydraulic press.

Importance of Seal Kits

The importance of hydraulic press seal kits cannot be overstated. First and foremost, they play a crucial role in maintaining the integrity of hydraulic systems. Any leakage of hydraulic fluid can lead to a decrease in pressure, affecting the overall performance of the press. This can result in underperformance, increased wear and tear, and potentially catastrophic failures, which can halt production and lead to costly repairs.

Secondly, seal kits contribute to the safety of hydraulic operations. A well-functioning seal prevents the escape of hydraulic fluids, which can be hazardous. Hydraulic oil leaks can create slippery surfaces, increasing the risk of accidents in the workplace. Moreover, in systems that operate under high pressure, a failure in the sealing mechanism can lead to sudden bursts, posing safety risks to operators and machinery alike.

Components of a Hydraulic Press Seal Kit

1. O-Rings These are circular seals made from rubber or thermoplastic materials, designed to fit inside a groove to create a seal force when compressed. They are commonly used to prevent fluid from leaking between two parts.

2. Piston Seals These are used to seal the area around the piston rod, preventing fluid from escaping and ensuring efficient movement. They provide a critical barrier between the hydraulic fluid and the environment.

hydraulic press seal kit

3. Fluid Seals Fluid seals are designed to hold hydraulic fluid in place while allowing for movement. They are essential in applications where there is relative motion between components.

4. Backup Rings These rings support the O-rings and piston seals, providing additional protection against extrusion and enhancing the longevity of the seals.

Maintenance Tips for Hydraulic Press Seal Kits

To ensure the longevity and efficiency of hydraulic press seal kits, regular inspection and maintenance are crucial. Here are some essential tips

- Regular Inspections Frequently check for signs of wear or damage to seals and gaskets. Early detection of leaks can save time and costs associated with extensive repairs.

- Proper Lubrication Ensure that all components are adequately lubricated to minimize friction and wear.

- Temperature Management Monitor the operating temperature of the hydraulic system. Excessive heat can degrade seals and lead to premature failure.

- Usage of Quality Parts Always use original or high-quality replacement seals to maintain system efficiency and reliability.

In conclusion, hydraulic press seal kits are fundamental to the efficient and safe operation of hydraulic presses. Understanding their components and maintaining them properly is crucial for optimal performance and longevity of hydraulic systems. By taking the necessary precautions and engaging in regular maintenance, operators can ensure the reliability and safety of their hydraulic equipment.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories