2 月 . 18, 2025 11:59 Back to list

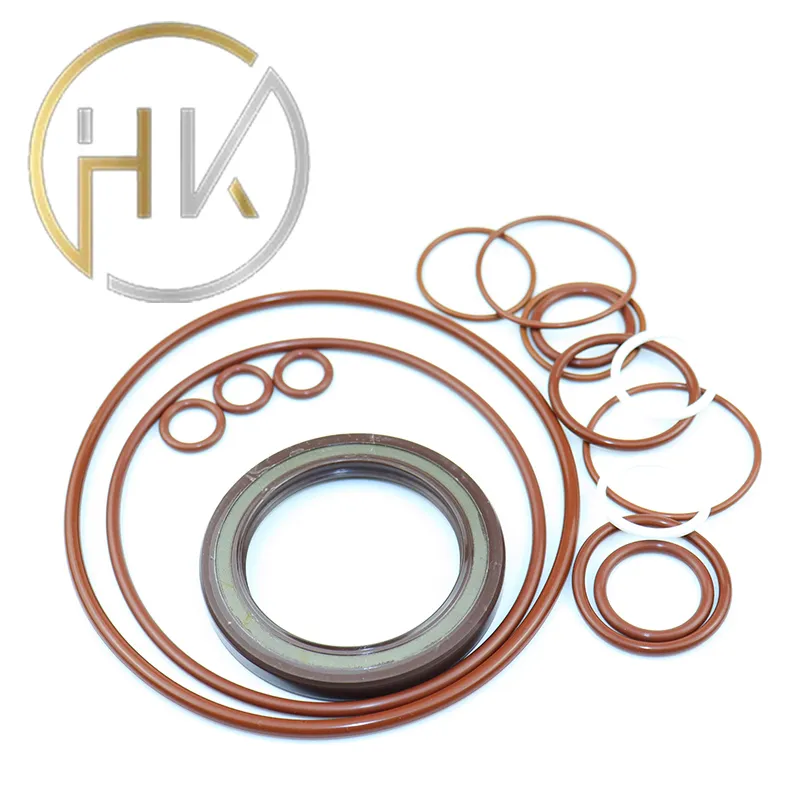

Standard High Pressure TCV Type Hydraulic Oil Seal

Trustworthiness in the realm of hydraulic seal kits is largely derived from manufacturer reputation and innovation. Trusted brands employ advanced manufacturing techniques, including precision molding and CNC machining, to deliver seals with exacting tolerances that meet or exceed industry specifications. Moreover, these manufacturers often engage in rigorous testing protocols, including endurance and leakage tests, simulating real-world conditions to validate seal performance. For system operators, the expertise in selecting and maintaining a hydraulic piston seal kit translates into significant operational benefits. By mitigating the risks of fluid leakage and mechanical wear, seal kits protect the environment from fluid contamination and enhance the safety and efficiency of hydraulic systems. Furthermore, they contribute to cost efficiency by reducing the frequency and intensity of maintenance necessities. In practice, replacing or upgrading a hydraulic piston seal kit should be approached strategically. It involves evaluating the compatibility of the seal materials with the hydraulic fluid, the operating temperature range, and pressure conditions. Consulting with industry experts or utilizing manufacturer advisory resources can further optimize seal kit selection and application, providing additional layers of reliability and assurance. Finally, staying abreast of technological advancements and material science developments is crucial. Emerging technologies in lubrication and material formulations promise even greater efficiency gains and longevity, reducing the ecological footprint of hydraulic systems. By integrating such innovations into operational frameworks, professionals reaffirm their commitment to sustainability and operational excellence. In conclusion, a hydraulic piston seal kit is more than just a collection of mechanical components; it is an essential investment in operational reliability and longevity. With the right expertise and resources, system operators can harness the full potential of these kits, driving performance in even the most demanding hydraulic applications.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories