10 月 . 21, 2024 16:41 Back to list

Hydraulic Piston Seals for Efficient Oil Leakage Prevention and Performance Optimization

Understanding Hydraulic Piston Oil Seals

Hydraulic systems are integral to modern machinery, providing the necessary power and movement across various applications. Among the crucial components within these systems are hydraulic piston oil seals. These seals are vital for ensuring the efficient and reliable operation of hydraulic cylinders, preventing leakage, and maintaining system integrity. In this article, we delve into the function, types, and significance of hydraulic piston oil seals.

The Role of Hydraulic Piston Oil Seals

The primary function of hydraulic piston oil seals is to provide a barrier that prevents hydraulic fluid from escaping the cylinder while also keeping contaminants out. As hydraulic pistons move, they create a high-pressure environment that could lead to fluid loss if leaks occur. Oil seals not only help maintain the pressure necessary for smooth operation but also protect the internal components of the cylinder from external contaminants like dirt, dust, and moisture.

Additionally, hydraulic piston oil seals play a critical role in enhancing performance. By maintaining the appropriate pressure within the system, they ensure that hydraulic machinery operates efficiently, which translates into reduced energy consumption and lower operational costs. Moreover, effective sealing prevents unwanted wear and tear on components, ultimately extending the lifespan of hydraulic systems.

Types of Hydraulic Piston Oil Seals

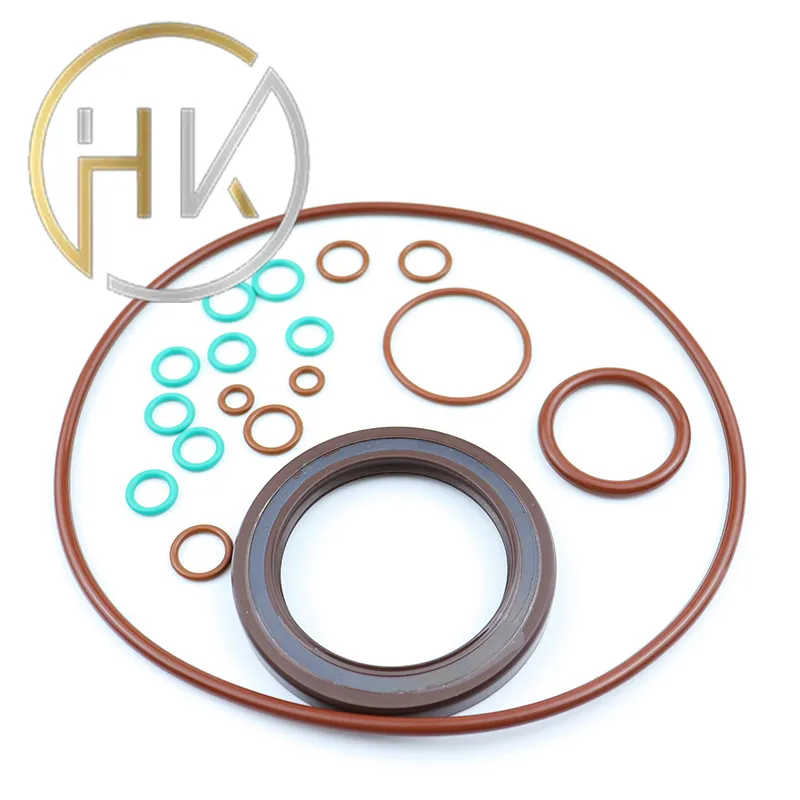

Hydraulic piston oil seals come in various designs and materials, each suited for specific applications and operating conditions. The most common types include

1. U-Cup Seals Named for their U-shaped profile, U-cup seals are widely used in hydraulic applications. They provide excellent sealing performance under both low and high-pressure conditions. The design allows for easy installation and replacement, making them a popular choice for many industries.

hydraulic piston oil seals

2. O-Rings These circular seals are used in a variety of applications, offering flexibility in sealing and resistance to a wide range of fluids. While O-rings are effective in static applications, they can also serve dynamic applications depending on the design and material.

3. V-Ring Seals V-rings are designed for shaft sealing and can accommodate axial movements, making them ideal for applications where radial displacement occurs. They provide good sealing in dirty environments, which adds to their versatility.

4. Lip Seals These seals feature a flexible lip that adapts to the surface of the piston, creating a tight seal against the hydraulic fluid. Lip seals are particularly useful for high-speed applications and can be designed to handle various pressures.

Choosing the Right Seal

Selecting the appropriate hydraulic piston oil seal involves considering several factors, including the operating pressure, temperature range, and the type of hydraulic fluid. The material of the seal is also crucial; common materials include rubber (such as nitrile and polyurethane), PTFE, and other elastomers. Each material has specific properties that make it better suited for certain applications.

In addition, proper installation and maintenance are essential for ensuring the longevity and effectiveness of hydraulic piston oil seals. Misalignment, contamination, and incorrect fitting can lead to premature seal failure, resulting in costly downtime and repairs.

Conclusion

Hydraulic piston oil seals, while often overlooked, are fundamental components that significantly impact the performance and reliability of hydraulic systems. Understanding their function, types, and the importance of proper selection and maintenance can help engineers and operators enhance the efficiency of their hydraulic machinery. As technology advances, the design and materials of hydraulic seals continue to evolve, ensuring that they meet the demands of modern applications and contribute to the overall efficiency of hydraulic systems.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories