10 月 . 30, 2024 20:46 Back to list

hydraulic oil seal types

Understanding Hydraulic Oil Seal Types

Hydraulic systems are critical components in various machinery and vehicles, relying on hydraulic fluid to transmit power efficiently. Central to the performance and reliability of these systems are hydraulic oil seals, which prevent fluid leaks and contamination, ensuring smooth operation. There are several types of hydraulic oil seals, each designed to suit specific applications and operating conditions.

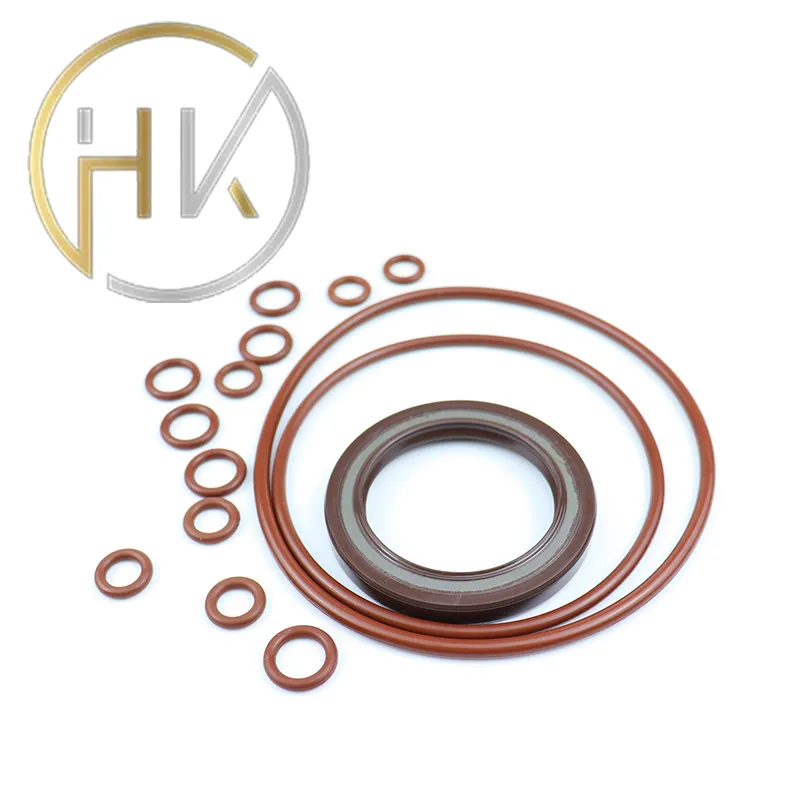

1. O-Ring Seals

O-ring seals are one of the most common types used in hydraulic systems. They are circular, rubber rings that compress between two surfaces, creating a tight seal to prevent fluid leakage. O-rings are versatile, available in a range of materials, such as nitrile, fluorocarbon, and silicone, allowing them to withstand various temperatures and chemical environments. Their simplicity and effectiveness make them a popular choice in hydraulic applications, but they must be selected carefully to match the system’s pressure and temperature requirements.

2. U-Cup Seals

U-cup seals, also known as U-packings, have a unique shape that resembles the letter U. These seals work effectively in both static and dynamic applications, making them suitable for rods and pistons. U-cups are often made from elastomer materials and are designed to provide low-friction sealing, which is essential in hydraulic systems to maintain efficiency. Their design also allows them to be easily replaced, minimizing downtime during maintenance.

3. V-Ring Seals

hydraulic oil seal types

V-ring seals are another popular option in hydraulic applications. They are made from elastomeric compounds and are shaped like a V. These seals are particularly effective for rotating shafts, providing a reliable seal against dirt and moisture while allowing for some axial movement. V-rings are often used in conjunction with other types of seals for enhanced protection and to extend the longevity of hydraulic systems.

4. Lip Seals

Lip seals, or radial shaft seals, consist of a flexible lip that contacts the shaft and a body that is fixed to the housing. These seals are ideal for preventing the escape of hydraulic oil while keeping contaminants out. They are commonly used in hydraulic cylinders and other rotating equipment. The design of lip seals allows for low friction and excellent sealing capability, which contributes to the overall efficiency of hydraulic systems.

5. Composite Seals

Composite seals comprise multiple materials to combine the best properties of different sealing solutions. Typically, they might include elastomeric compounds along with metallic or other materials that enhance durability and resistance to harsh environments. These seals are customizable and can be tailored to meet specific application requirements, making them suitable for high-performance hydraulic systems.

Conclusion

Choosing the right hydraulic oil seal is crucial for the performance and reliability of hydraulic systems. Understanding the various types available, including O-rings, U-cups, V-rings, lip seals, and composite seals, allows engineers and mechanics to make informed decisions based on the specific needs of their applications. By ensuring proper sealing, these components help maintain pressure, reduce maintenance costs, and improve the overall efficiency of hydraulic machinery, leading to longer service life and improved operational reliability. Proper selection and maintenance of hydraulic seals not only optimize performance but also enhance the safety and functionality of hydraulic systems.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories