10 月 . 19, 2024 12:28 Back to list

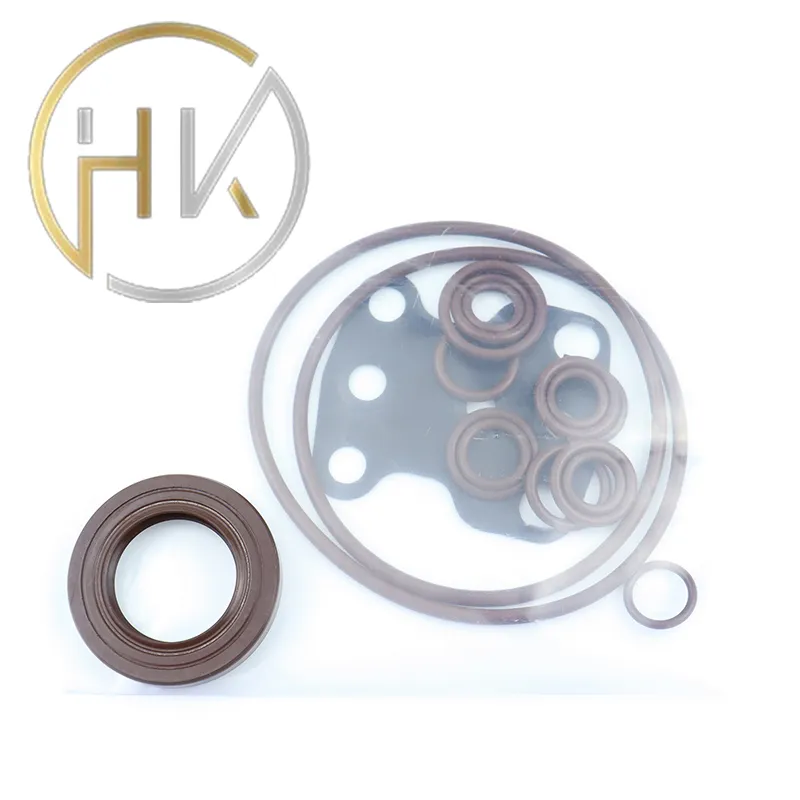

hydraulic oil seal suppliers

The Importance of Selecting Quality Hydraulic Oil Seal Suppliers

In the world of industrial machinery and equipment, hydraulic systems play a vital role in ensuring efficient operation. One essential component of these systems is the hydraulic oil seal. Oil seals prevent fluid leakage and protect sensitive internal components from contaminants, thereby enhancing the performance and longevity of hydraulic systems. The selection of reliable hydraulic oil seal suppliers is crucial for maintaining the integrity of hydraulic systems.

Understanding Hydraulic Oil Seals

Hydraulic oil seals, often made from materials like rubber, polyurethane, or metal, are designed to create a tight seal between stationary and moving parts in hydraulic applications. They help to contain hydraulic fluid within the system, preventing leaks that can lead to reduced efficiency and potential damage. High-quality seals not only ensure optimal performance but also contribute to the safety and reliability of hydraulic equipment.

The market offers a variety of hydraulic oil seals, each tailored for specific applications and conditions. Factors such as temperature, pressure, and the type of hydraulic fluid used must be considered when selecting seals. This is where the importance of sourcing from reputable suppliers becomes apparent.

Why Quality Matters

Opting for quality hydraulic oil seals is paramount. Poorly manufactured seals can lead to premature wear, increased maintenance costs, and catastrophic failures. Unlike regular components, oil seals operate under extreme conditions; therefore, their durability is directly linked to the design and material quality. Suppliers with a track record of excellence typically conduct thorough testing and adhere to strict manufacturing standards. This means that their products are more likely to withstand the rigors of hydraulic applications, reducing the risk of leaks and downtime.

Moreover, using subpar seals can significantly impact the efficiency of hydraulic systems. Even the slightest leak can result in a loss of pressure, negatively affecting the machinery's overall performance. In industries where precision and reliability are critical, such as aerospace, automotive, and manufacturing, the choice of oil seal supplier can directly influence productivity and operational costs.

Choosing the Right Supplier

hydraulic oil seal suppliers

When it comes to selecting a hydraulic oil seal supplier, several factors should be considered

1. Reputation and Experience Look for suppliers with a proven history in the industry. Established companies often have extensive experience in producing high-quality seals and can offer valuable insights regarding the best products for specific applications.

2. Product Range A reputable supplier should have a diverse range of oil seals to accommodate various hydraulic systems. This ensures that customers can find the exact seal they need without having to compromise on quality or fit.

3. Customization Options In many cases, standard seals may not meet the specific needs of a hydraulic system. A good supplier should be able to offer customization services to produce seals that fit unique requirements, whether related to size, material, or design.

4. Quality Assurance Suppliers should have robust quality control procedures in place. This includes testing their products under various conditions to ensure performance and reliability. Certificates of compliance and quality standards, such as ISO certifications, are indicators of a supplier's commitment to excellence.

5. Customer Support Finally, effective customer support can make a significant difference in supplier selection. A supplier that is responsive and knowledgeable can provide essential assistance in product selection, installation guidance, and troubleshooting.

Conclusion

The hydraulic oil seal is an integral component in ensuring the efficiency and longevity of hydraulic systems. Choosing the right supplier is essential to secure high-quality seals that meet the specific needs of various applications. By considering factors such as reputation, product range, customization options, quality assurance, and customer support, businesses can make informed decisions that will ultimately lead to enhanced operational performance, reduced maintenance costs, and minimized downtime. Investing time and effort into selecting a reliable hydraulic oil seal supplier is not just a prudent business decision; it is a commitment to ensuring the durability and efficiency of machinery that drives industries forward.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories