3 月 . 06, 2025 14:44 Back to list

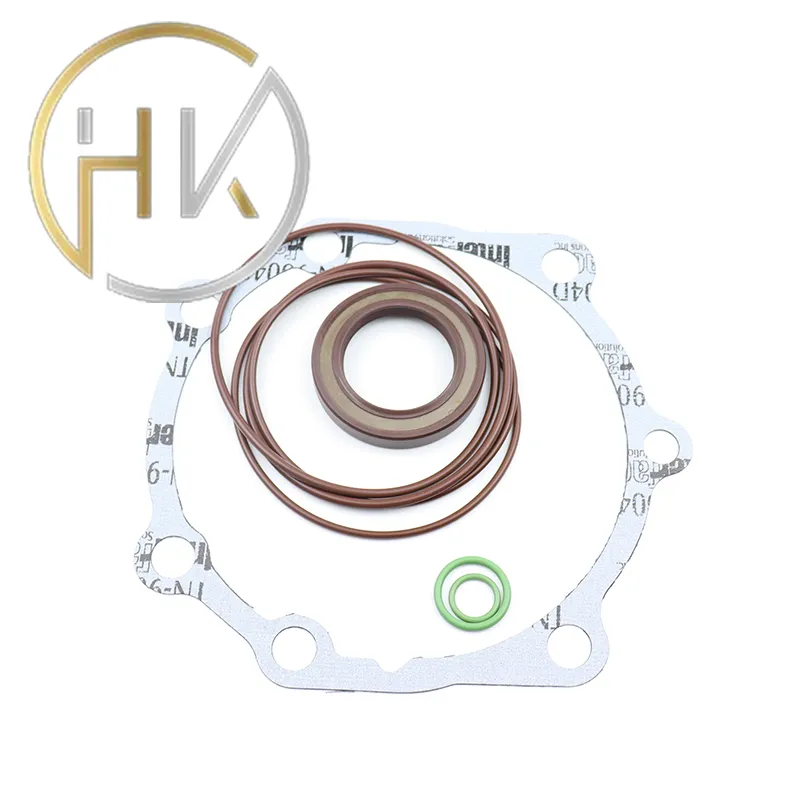

agricultural seals

Ensuring trustworthiness involves rigorous testing and certifications that uphold the highest standards in manufacturing. Product certifications from recognized bodies enhance customer trust, ensuring the hydraulic motor seals meet stringent quality and safety standards. Users should look for seals that comply with industry standards such as the ISO 9001 for quality management and ISO 14001 for environmental management. For industry professionals seeking to improve their knowledge about hydraulic motor seals, it is beneficial to engage with communities and forums focused on hydraulic systems. These platforms are rich with shared experiences and insights from technicians and engineers who have tested various products and solutions in real-world scenarios. Leveraging this accumulated wisdom can guide new users in selecting seals that best fit their specific applications. Moreover, practical experience plays a substantial role in understanding the nuances of hydraulic motor seal application. Technicians and engineers regularly document and share their findings about seal performance over time, offering valuable insights into maintenance schedules and replacement intervals. Such documentation not only aids in extending the lifespan of hydraulic systems but also fosters a culture of continuous improvement and operational excellence. In conclusion, investing in superior hydraulic motor seals yields long-term benefits such as increased system efficiency, reduced maintenance costs, and improved equipment reliability. By choosing seals that align with specific operational requirements, industry experts can achieve optimal performance and extend the life of their hydraulic systems. This nuanced understanding of hydraulic motor seals underscores their vital role in the sustained success of industries reliant on hydraulic systems.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories