9 月 . 22, 2024 19:14 Back to list

hydraulic lift cylinder seal kits

Hydraulic Lift Cylinder Seal Kits Essential Components for Performance and Longevity

Hydraulic systems are integral to numerous industrial applications, from construction machinery to automotive shops. At the heart of these systems are hydraulic lift cylinders, which rely on specialized seals to function effectively. Hydraulic lift cylinder seal kits are crucial for maintaining the performance, safety, and longevity of hydraulic cylinders, ensuring that they operate smoothly under pressure.

Hydraulic cylinders work by converting hydraulic energy into mechanical energy, creating movement through the use of fluids. The seals within these cylinders play a vital role by preventing leaks, maintaining pressure, and ensuring that the hydraulic fluid remains contained. Without effective seals, the hydraulic system could experience reduced efficiency, leading to failures that may result in costly downtime and repairs.

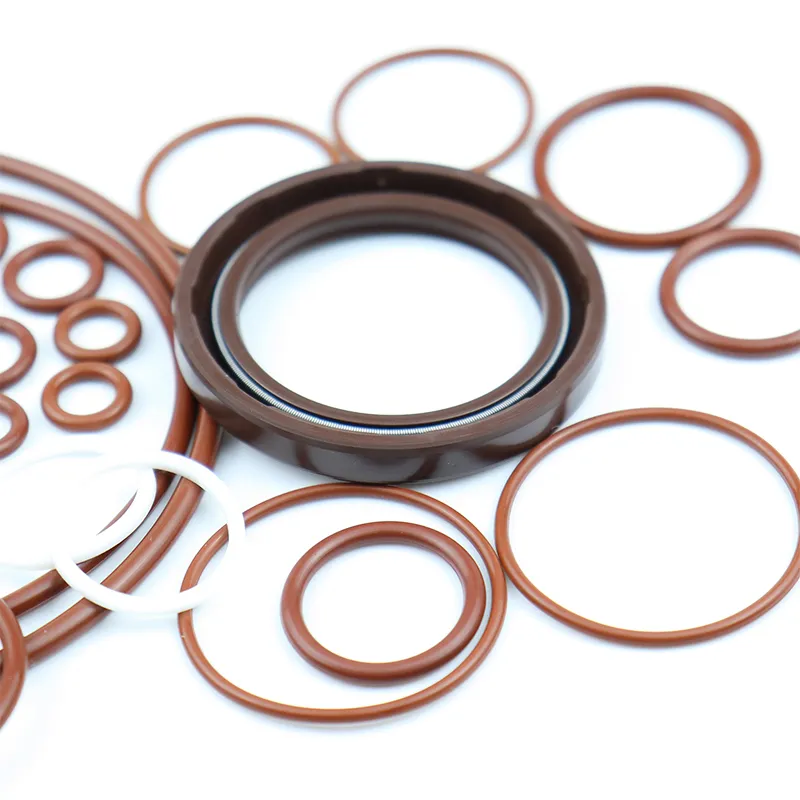

Seal kits are specifically designed to maintain the integrity of hydraulic lift cylinders. These kits include various types of seals, such as O-rings, piston seals, rod seals, and backup rings. Each type of seal serves a unique function, working together to create a reliable barrier against fluid leakage. For example, O-rings are commonly used to seal static joints, while rod seals are used to prevent fluid from leaking past the moving rod.

hydraulic lift cylinder seal kits

Selecting the right seal kit is critical for optimal performance. The seals must be compatible with the hydraulic fluid being used, as well as capable of withstanding the pressure and temperature variations present in the system. Additionally, the materials used for seals, such as polyurethane, rubber, or PTFE, should be chosen based on the specific application and the oil's properties. High-quality materials ensure that the seals have a longer lifespan and can withstand wear and tear over time.

One of the primary benefits of using hydraulic lift cylinder seal kits is the cost-effectiveness they offer. Regular maintenance and timely replacement of seals can prevent major breakdowns and extend the life of the hydraulic cylinder. This proactive approach not only avoids expensive repairs but also enhances the overall efficiency of the hydraulic system. When seals begin to wear out, they can compromise the system’s performance, leading to inefficiencies that can significantly increase operational costs.

Moreover, using professionally manufactured seal kits ensures that the seals meet industry standards for quality and safety. Reliable seal kits are often backed by warranties, providing additional peace of mind to users. It's also essential for operators and maintenance personnel to be familiar with the signs of seal deterioration, such as leaks, reduced lift capacity, and increased noise levels, so they can address issues promptly.

In conclusion, hydraulic lift cylinder seal kits are indispensable for the performance and reliability of hydraulic systems. By utilizing the right seal kits and committing to regular maintenance, operators can ensure that their hydraulic cylinders function optimally, minimizing the risk of failure. As industries continue to evolve and rely on hydraulic technology, understanding and investing in quality seal kits will remain essential for sustaining effective and efficient operations.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories