10 月 . 13, 2024 11:24 Back to list

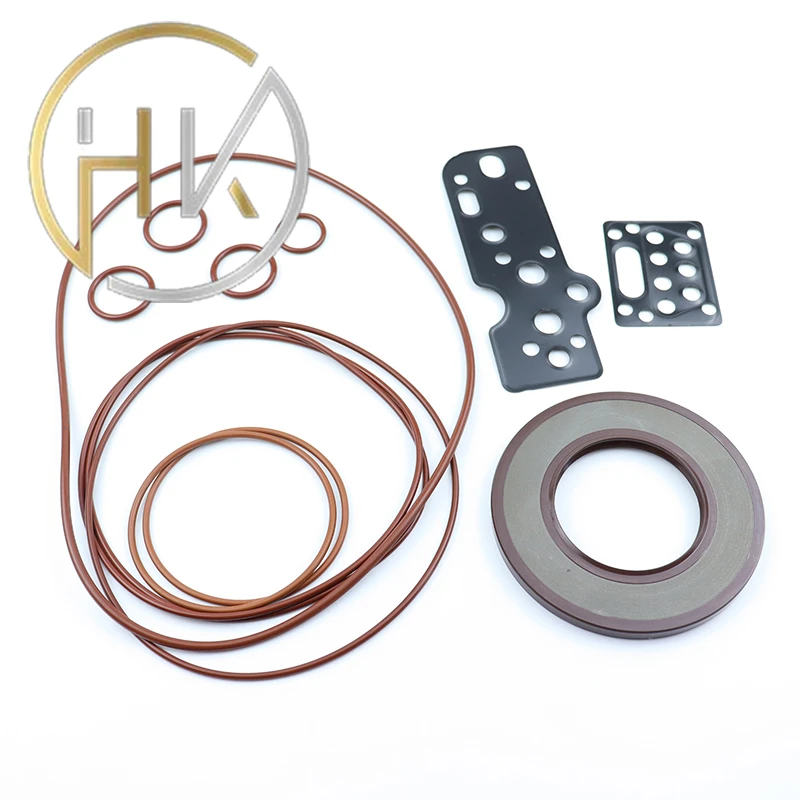

hydraulic lift cylinder seal kits

Understanding Hydraulic Lift Cylinder Seal Kits

Hydraulic systems are integral to a multitude of machinery, from industrial equipment to automotive applications. Among the various components that ensure successful operation, hydraulic lift cylinders are particularly crucial for lifting and supporting heavy loads. However, for these cylinders to function optimally, they must be equipped with reliable seal kits. This article delves into the significance of hydraulic lift cylinder seal kits, their components, and best practices for maintenance.

What Are Hydraulic Lift Cylinder Seal Kits?

Hydraulic lift cylinder seal kits are specially designed assemblies that contain seals, O-rings, and other components necessary to support the cylinder's operation. The primary function of these seals is to prevent hydraulic fluid from leaking out of the cylinder while also keeping contaminants from entering. A well-functioning seal kit will ensure efficient operation, reduce wear and tear on the cylinder, and ultimately extend its lifespan.

Components of Seal Kits

These kits typically include various components tailored to the specific hydraulic cylinder design. Key elements often found in seal kits include

1. Dynamic Seals These seals facilitate the movement between the cylinder rod and the cylinder bore. They need to withstand high pressures and provide a tight seal to prevent fluid leakage during the lifting process.

2. Static Seals These are used in areas where there's no relative movement. They provide a seal at joints and end caps, preventing leakage without the concern of dynamic wear and tear.

3. O-rings These provide a secondary layer of sealing. Although tiny, O-rings play a vital role in ensuring that the hydraulic fluid remains contained within the cylinder and that dirt and moisture do not infiltrate.

4. Back-up Rings These are placed behind dynamic seals to prevent extrusion under high pressure, adding an extra layer of protection against leaks.

hydraulic lift cylinder seal kits

Importance of Quality in Seal Kits

The quality of hydraulic lift cylinder seal kits is paramount. Using inferior materials can lead to premature wear, increased leakage, and ultimately, system failure. High-quality seals are made from durable materials, such as polyurethane or rubber compounds, that withstand high pressures, extreme temperatures, and the corrosive properties of hydraulic fluids. Insufficient quality can result in costly repairs and significant downtime in operations.

Regular Maintenance Practices

To ensure the longevity and reliability of hydraulic lift cylinders, regular maintenance is essential. Here are some best practices

1. Routine Inspections Regularly checking for signs of wear, such as leaks or dust accumulation, can help identify potential problems before they escalate.

2. Fluid Maintenance Keeping the hydraulic fluid clean and at appropriate levels is crucial. Contaminated or insufficient fluid may cause excessive wear on seals and other components.

3. Timely Replacement Seal kits should be replaced at the recommended intervals, or sooner if significant wear is observed. This proactive approach will help avoid sudden failures.

4. Proper Installation When replacing seal kits, ensuring correct installation is vital. Misalignment or improper fitting can lead to immediate leaks and reduced performance.

Conclusion

Hydraulic lift cylinder seal kits are essential for the effective and efficient operation of hydraulic systems. Understanding their components, ensuring quality, and adhering to regular maintenance practices contribute to the longevity of hydraulic cylinders. As industries increasingly rely on hydraulic systems, investing in reliable seal kits and following best maintenance practices will enhance performance, reduce downtime, and ultimately lead to greater productivity and cost savings.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories