2 月 . 14, 2025 11:00 Back to list

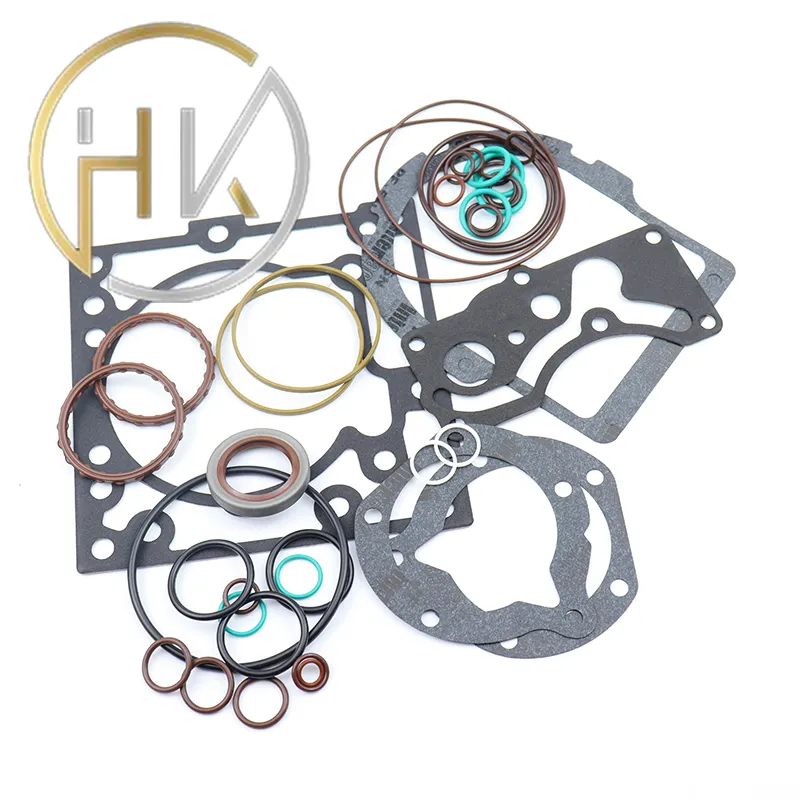

hydraulic jack repair kits

Opting for hydraulic jack repair kits from reputable manufacturers is a decision grounded in expert advice. These manufacturers are often leaders in the hydraulic tools industry, boasting years of experience and a reputation for quality. Their kits pass through rigorous quality control processes, ensuring each component meets industry standards. By choosing products from these authoritative sources, users can be confident in the reliability and performance of their repairs. Equally important is routine maintenance, an often-overlooked aspect of hydraulic jack care. Regular inspections for leaks, fluid levels, and seal integrity are preventive measures that mitigate the onset of more severe problems. Some kits even include testing tools, enabling users to perform diagnostic checks and maintain their equipment in optimum condition. Each repair not only rejuvenates the jack’s lifting power but also instills a sense of trustworthiness with the repaired equipment. Users confident in their tools project professionalism, which is invaluable in any line of work. Moreover, the mindfulness gained from investigating and resolving issues contributes to a broader understanding of hydraulic systems, enhancing the user’s expertise. Hydraulic jack repair kits empower users, merging practical experience with professional standards. By preserving the functionality of hydraulic jacks, these kits reinforce the principle that well-maintained equipment is paramount to operational success. What might seem a straightforward task of replacing seals becomes an exercise in quality assurance, embodying the essential elements of Experience, Expertise, Authoritativeness, and Trustworthiness.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories