10 月 . 30, 2024 22:58 Back to list

hydraulic jack repair kits

Understanding Hydraulic Jack Repair Kits

Hydraulic jacks are essential tools in various industries, enabling the lifting of heavy loads with ease. However, like any mechanical device, they are prone to wear and tear over time due to regular use. This is where hydraulic jack repair kits come into play. These kits are designed to restore the functionality of hydraulic jacks and extend their lifespan.

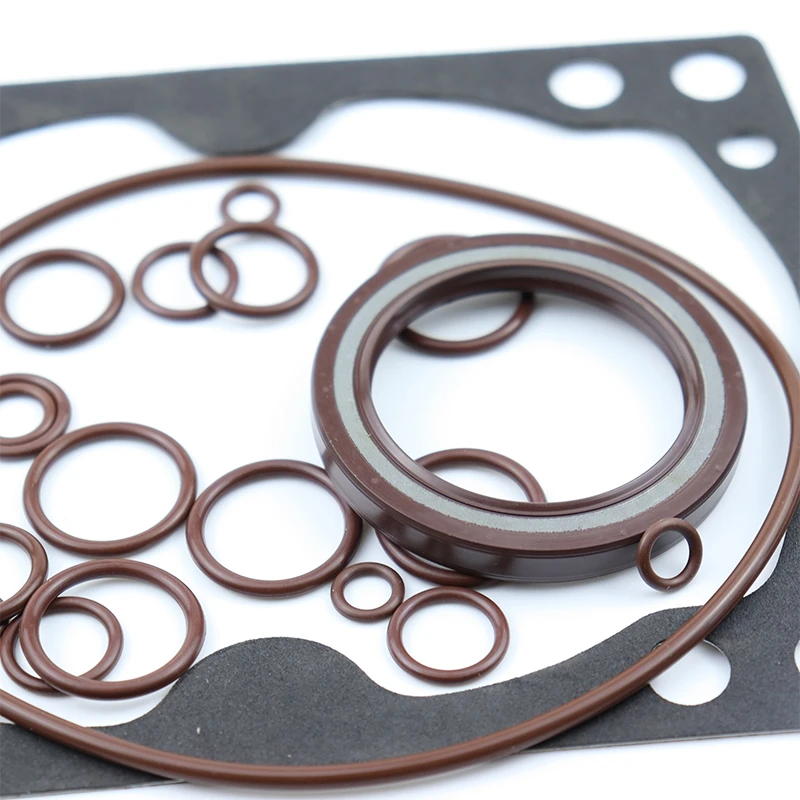

A typical hydraulic jack repair kit contains all the necessary components to fix common issues associated with hydraulic jacks. These components often include seals, O-rings, piston cups, and sometimes even complete pistons. The materials used for these components are typically high-quality rubber or synthetic materials that can withstand the pressures and fluids common in hydraulic systems. Using a repair kit can save users both time and money compared to replacing an entire jack.

One of the most common issues hydraulic jacks face is leakage. Over time, seals and O-rings can become worn or damaged, leading to fluid loss and reduced lifting capacity. When you notice that your jack is losing pressure or is unable to lift loads effectively, it’s a sign that a repair kit may be necessary. By replacing the worn components with those from a repair kit, you can restore the hydraulic jack to optimal performance without the need for a complete replacement.

hydraulic jack repair kits

When selecting a hydraulic jack repair kit, it's vital to choose one that is compatible with your specific model of jack. Different manufacturers may use varying sizes and shapes of components, so always consult the user manual or manufacturer specifications before purchasing. Many repair kits come with detailed instructions, making the installation process straightforward. Even those with only a basic understanding of mechanical systems can often perform the repairs with relative ease.

In addition to regular maintenance and using repair kits, it is also essential to follow best practices for hydraulic jack use. Always ensure that the jack is placed on a stable and level surface before lifting any loads. Avoid overloading the jack, as this can cause undue stress on its components and lead to failure. Regularly check for signs of wear or damage, and address any issues promptly to avoid more significant problems down the line.

Moreover, proper storage of the hydraulic jack can significantly affect its longevity. After use, ensure that the jack is cleaned and stored in a dry place to prevent corrosion. Keeping the hydraulic jack free from debris and contaminants will also help maintain its functionality.

In conclusion, hydraulic jack repair kits are an invaluable resource for anyone who regularly uses hydraulic jacks. They provide a cost-effective solution for addressing wear and tear, allowing users to maintain their equipment effectively. By understanding the components and proper use of these repair kits, along with implementing good maintenance practices, you can ensure that your hydraulic jack remains reliable for years to come. Investing time in learning about these kits not only enhances your operational efficiency but also promotes safety in the workplace.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories