3 月 . 06, 2025 13:05 Back to list

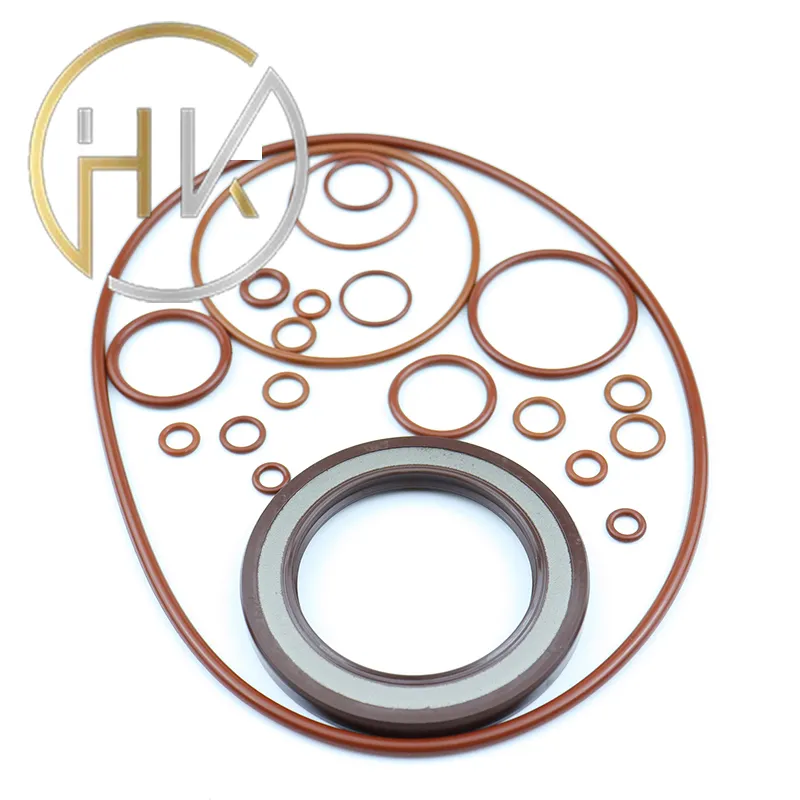

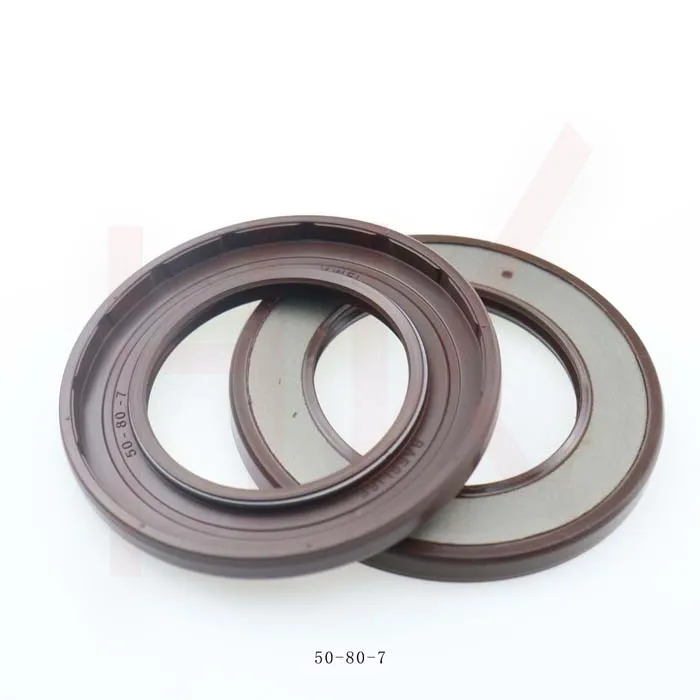

agricultural seals

Authoritativeness in the hydraulic industry often ties back to the quality and reliability of the components used. OEM (Original Equipment Manufacturer) seals are often recommended to ensure compatibility and durability. These seals are specifically designed to meet the specifications of the hydraulic gear pumps they are intended for, providing an assurance of performance and reliability that aftermarket parts may not consistently offer. Trustworthiness in the context of hydraulic gear pump seals can be measured by the seal's track record and the manufacturer's reputation. Established manufacturers with a history of delivering high-quality sealing solutions are usually preferred. They often provide extensive documentation, including installation guides and maintenance tips, further enhancing their credibility. Experience in dealing with hydraulic gear pump seals also highlights the significance of installation and alignment. Improper installation can lead to premature seal failure, regardless of the seal's material or design. Therefore, following the manufacturer's guidelines and seeking professional assistance during installation can prevent potential operational setbacks. In conclusion, hydraulic gear pump seals are indispensable for the efficient operation of hydraulic systems. Their selection, maintenance, and the quality of the seals themselves directly impact the system's reliability and efficiency. By prioritizing expertise, authoritativeness, and trustworthiness in choosing and managing these seals, businesses can ensure their hydraulic systems run smoothly, avoiding costly downtime and repairs. Investing in high-quality seals from reputable manufacturers, coupled with adherence to maintenance protocols, is a proven strategy for enhancing system longevity and performance.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories