2 月 . 11, 2025 21:27 Back to list

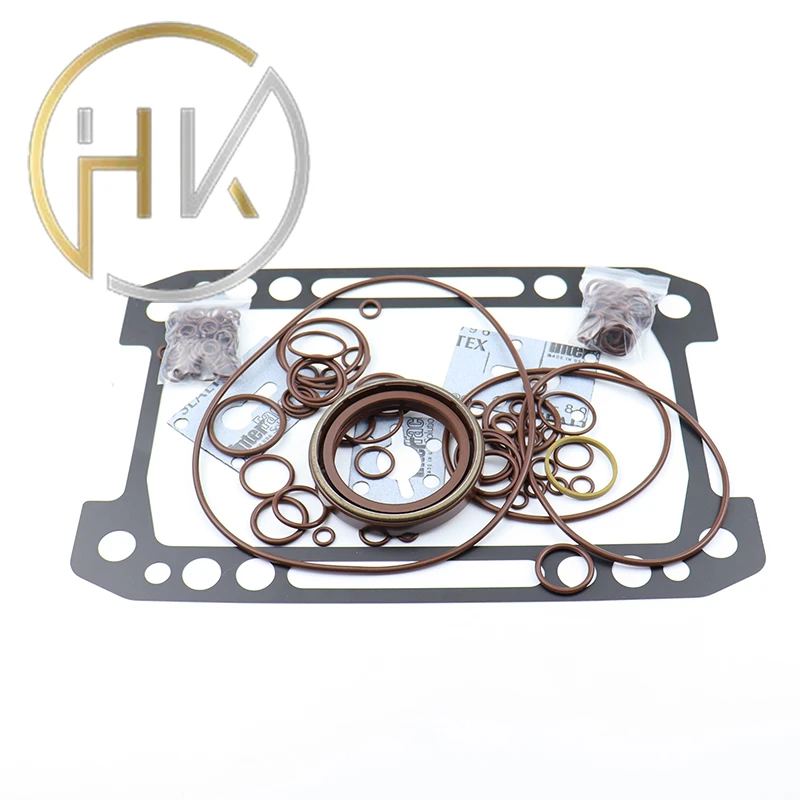

hydraulic gear pump seal kit

Transitioning into actionable advice, proper installation is as crucial as selecting the right seal kit. A common pitfall is the improper handling of seals during installation, leading to nicks or improper seating, which ultimately culminates in seal failure. Professionals stress on following step-by-step guidelines provided by manufacturers and using appropriate tools. Additionally, ensuring a clean, dust-free environment during installation significantly enhances the seal performance and lifespan. Trustworthiness also comes into play when considering the lifecycle of a seal kit. Over-enthusiastic intervals of replacement might be unnecessarily cost-intensive. Based on expert evaluations and studies, maintaining a log to track the performance and lifecycle of seal kits leads to better decision-making, ensuring replacements occur at optimal times without premature or delayed substitutions. Leveraging prolonged exposure in the field, another key takeaway is the economic impact of well-maintained hydraulic gear pump seals on overall system efficiency. High-quality seals enhance pump performance, reduce energy consumption, and minimize environmental impact by containing potential leaks. This not only underlines the financial benefits but also affirms a commitment to sustainable practices. In conclusion, understanding the critical role of hydraulic gear pump seal kits enhances system reliability and operational efficiency. By emphasizing product expertise, installation best practices, and maintenance strategies, stakeholders can significantly optimize the performance and cost-effectiveness of their hydraulic systems. This level of detailed attention solidifies trust with clients and ensures that hydraulic systems function seamlessly in diverse working environments.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories