10 月 . 11, 2024 09:54 Back to list

hydraulic floor jack repair kit

Hydraulic Floor Jack Repair Kit A Comprehensive Guide

Hydraulic floor jacks are indispensable tools for anyone who frequently works on vehicles or heavy equipment. These robust machines enable users to lift substantial weights with minimal effort. However, like any mechanical device, hydraulic jacks are susceptible to wear and tear over time. The need for repairs may arise due to leaks, lowered lifting capabilities, or mechanical failures. This is where a hydraulic floor jack repair kit becomes an invaluable asset. In this guide, we will explore what a hydraulic floor jack repair kit typically contains, how to use it, and tips for maintenance to prolong the life of your jack.

What is a Hydraulic Floor Jack Repair Kit?

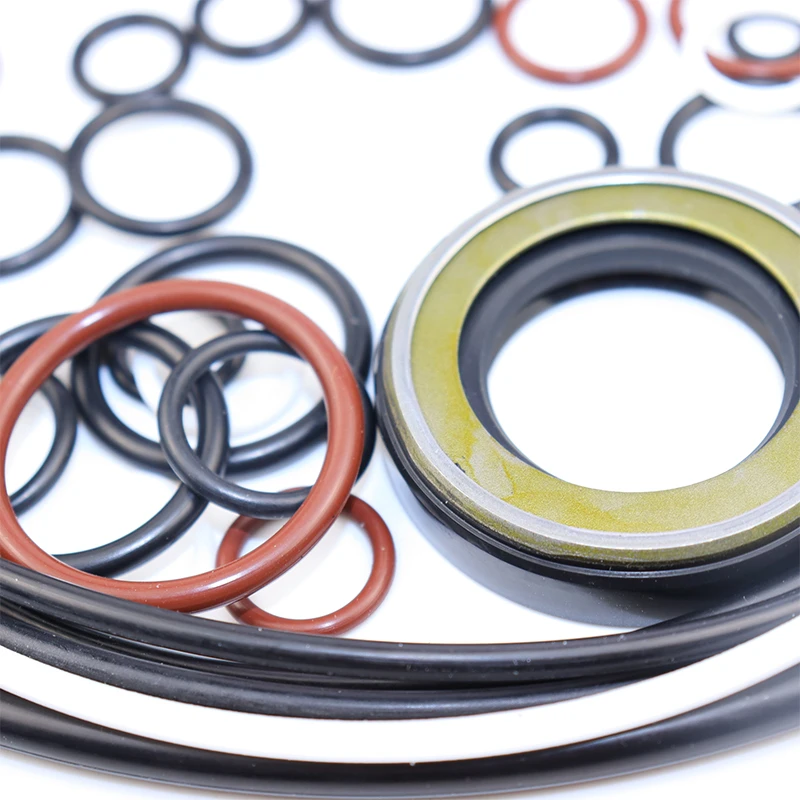

A hydraulic floor jack repair kit is designed to help users service and repair hydraulic floor jacks. These kits usually include a variety of essential components, such as O-rings, seals, hydraulic oil, a cylinder tool, and sometimes even comprehensive instructions for repairing common issues. The primary goal of a repair kit is to restore the jack's functionality, allowing it to lift loads efficiently and safely.

Common Issues Addressed by Repair Kits

1. Hydraulic Fluid Leaks One of the most common problems with hydraulic jacks is fluid leakage. Over time, seals can wear out, leading to decreased pressure and lifting capacity. A repair kit typically contains replacement seals and O-rings to fix these leaks.

2. Loss of Lifting Power If your jack struggles to lift loads it previously could handle, it may require maintenance. This condition could result from air entering the hydraulic system or a lack of hydraulic fluid. The repair kit often includes hydraulic oil to replenish the system.

3. Sticking or Jammed Mechanism If the jack does not operate smoothly, it might need cleaning or component replacement. A complete kit usually includes tools and parts necessary to address these mechanical issues.

4. Corrosion or Wear Corrosion can affect the cylinder, leading to inconsistencies in operation. A repair kit typically provides a new cylinder or parts to fix it, allowing for smoother and safer operations.

Using a Hydraulic Floor Jack Repair Kit

Before attempting any repairs, ensure safety. Always refer to the jack's manual for specific instructions related to your model. Here’s a step-by-step guide to using a repair kit

1. Identify the Issue Determine what is causing problems with your hydraulic jack. Look for signs of fluid leakage, excessive wear, or reduced lifting power.

hydraulic floor jack repair kit

2. Disassemble the Jack With the necessary tools from the repair kit, carefully disassemble the jack. Make sure to keep track of screws and components for easy reassembly.

3. Replace Damaged Parts Use the parts from your repair kit to replace any worn or damaged components, such as seals or O-rings.

4. Refill Hydraulic Fluid If your jack is low on fluid, refill it with the hydraulic oil provided in the kit. Ensure the oil level is adequate according to the manufacturer’s specifications.

5. Reassemble the Jack Carefully reassemble the jack, ensuring all parts are securely fastened.

6. Test the Jack After reassembly, conduct a test lift to ensure the jack operates smoothly at its full capacity.

Maintenance Tips for Longevity

To avoid frequent repairs and extend the life of your hydraulic floor jack, consider the following maintenance tips

- Regular Inspections Regularly examine your jack for signs of wear or damage, particularly in the seals and hydraulic fluid levels. - Proper Storage Store your jack in a clean, dry place to prevent rusting and corrosion. Avoid leaving it exposed to moisture.

- Fluid Change Periodically replace the hydraulic fluid, as contaminated fluid can lead to internal damage.

- Correct Usage Always use the jack according to the manufacturer's specifications to avoid undue strain and potential damage.

Conclusion

A hydraulic floor jack repair kit is essential for maintaining and restoring the functionality of your hydraulic jack. By understanding common issues and following proper maintenance guidelines, you can enhance your jack's performance and extend its lifespan. With some basic tools and knowledge, you can save money and avoid the hassle of unnecessary replacements, keeping your hydraulic floor jack in peak condition for years to come.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories