2 月 . 18, 2025 03:16 Back to list

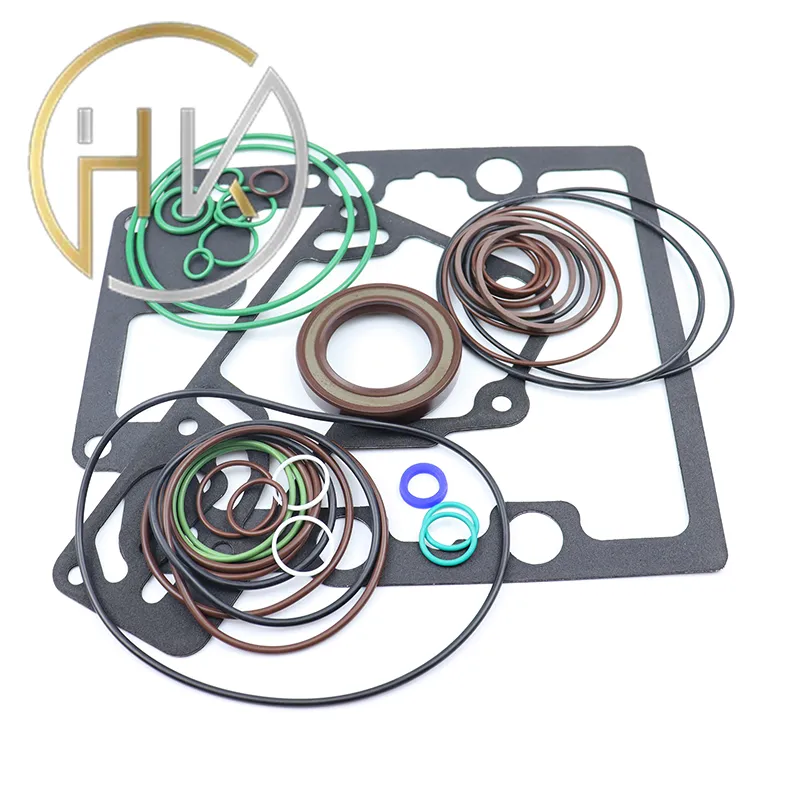

Standard Wheel Hub Oil Seal For Agricultural Machinery

Finding a trustworthy retailer or distributor is another crucial step in securing reliable hydraulic cylinder seals. A reputable seller will ensure that the product comes with a warranty and provide after-sales support which is key in building long-term trust and satisfaction. In addition, choosing certified seals ensures compliance with industry standards, further reinforcing trust. The significance of frequent maintenance and timely replacement of hydraulic cylinder seals cannot be understated. Preventative maintenance dramatically reduces the risk of unexpected breakdowns, extends the machinery's life, and optimizes operational efficiency. It also safeguards against the potentially high costs associated with large-scale repairs due to seal failures. For businesses seeking hydraulic cylinder seals for sale, their investment in quality, backed by expert guidance and trusted brand names, will pay off in the form of operational efficiency, reduced downtime, and prolonged equipment lifespan. Finding a knowledgeable supplier who understands these elements is vital. They bring not only product inventory but also a wealth of expertise and a commitment to helping you achieve the best possible outcomes with your hydraulic systems. In conclusion, hydraulic cylinder seals might seem minor compared to other machinery components, but they play a pivotal role in maintaining the operational integrity and efficiency of hydraulic systems. Opting for excellence in these seals contributes significantly to better performance and durability of equipment, making them a smart investment in reliability and trustworthiness.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories