2 月 . 13, 2025 20:51 Back to list

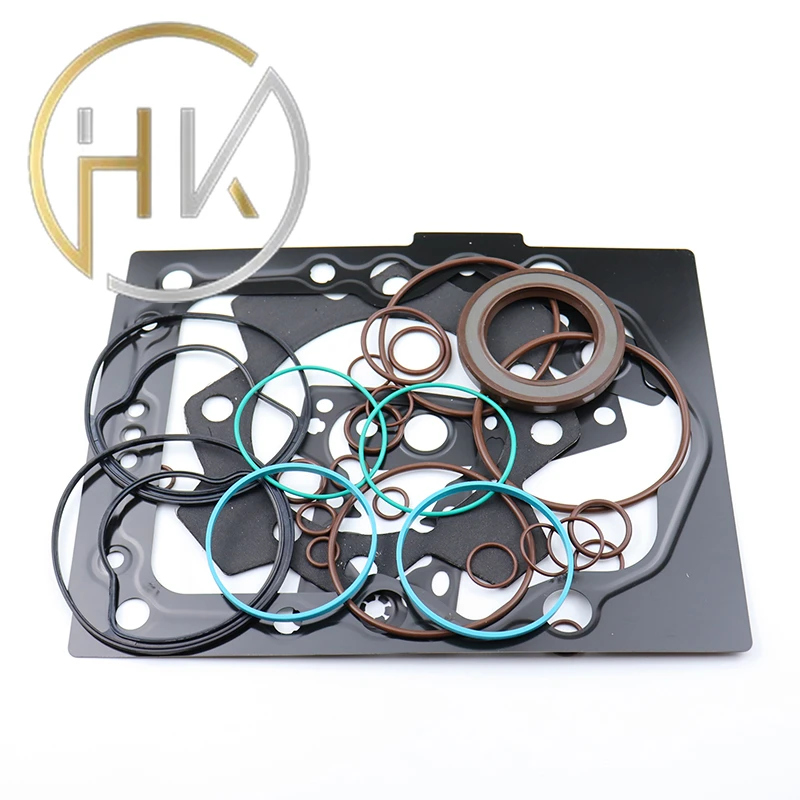

Standard Wheel Hub Oil Seal For Agricultural Machinery

The choice of hydraulic seals and wipers can also be influenced by the environmental conditions in which the hydraulic system operates. Systems exposed to extreme temperatures, aggressive chemicals, or abrasive materials require seals and wipers designed to withstand such conditions. This specialization not only enhances system resilience but also ensures that the hydraulic components function at peak efficiency, regardless of environmental challenges. Expertise in hydraulic seal and wiper technology continues to advance, with innovations focused on improving performance, durability, and sustainability. The development of composite materials, enhanced design techniques, and advanced coatings have all contributed to extending the life and effectiveness of these components. Such innovations are critical for staying ahead in industries where hydraulic systems are integral to operations. From a reliability perspective, selecting seals and wipers from reputable manufacturers known for their quality and innovation is crucial. Trusted brands often provide extensive testing and quality assurance, ensuring that their products meet or exceed industry standards. This reputation not only reinforces the trustworthiness of the hydraulic system but also aligns with best practices for minimizing operational risks. For professionals and businesses committed to maintaining efficient and reliable hydraulic systems, investing in high-quality seals and wipers is non-negotiable. The benefits of improved system longevity, reduced maintenance costs, and enhanced performance underscore the value of quality components. By prioritizing seals and wipers tailored to specific operational needs and conditions, businesses ensure that their hydraulic systems continue to power productivity and innovation across industries. In conclusion, hydraulic cylinder seals and wipers are more than mere components; they are essential custodians of system integrity and performance. Their role in containing fluid, excluding contaminants, and enduring harsh conditions underscores the expertise, authority, and trustworthiness needed to ensure optimal hydraulic operations. As industries evolve, staying informed and adaptive in the selection and maintenance of these critical components fosters a competitive edge grounded in reliability and efficiency.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories