9 月 . 25, 2024 05:40 Back to list

Hydraulic Cylinder Seal Kits for Enhanced Performance and Longevity in Machinery

Hydraulic Cylinder Seal Kits Ensuring Optimal Performance and Longevity

Hydraulic cylinders play a pivotal role in various machinery and equipment, transmitting force through fluid pressure to perform essential tasks. However, the efficiency and reliability of these cylinders largely depend on the quality of their seal kits. Hydraulic cylinder seal kits are critical components designed to prevent fluid leakage, maintain pressure, and protect against dirt and contaminants. In this article, we explore the importance of these seal kits, their composition, and best practices for maintenance.

Understanding Hydraulic Cylinder Seal Kits

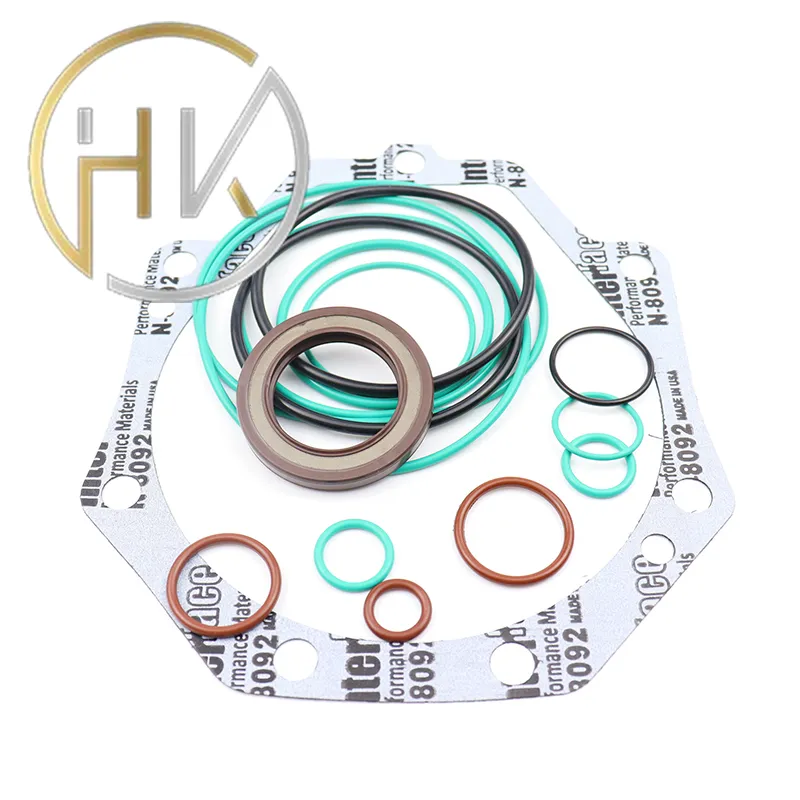

Hydraulic cylinder seal kits consist of multiple sealing elements, each serving a specific purpose in the hydraulic system. Common types of seals included in these kits are O-rings, rod seals, piston seals, and backup rings. O-rings prevent leakage at joint points, while rod and piston seals are crucial for maintaining the pressure within the cylinder. Backup rings provide additional support, preventing extrusion of the sealing material under high pressure.

Importance of Quality Seals

Using high-quality seal kits is essential for optimal hydraulic cylinder performance. Poor-quality seals can lead to premature failure, fluid leaks, and increased downtime for maintenance and repairs. This not only affects productivity but can also pose safety risks in industrial environments. Investing in reliable seal kits ensures that the hydraulic system operates efficiently, extending the life of the equipment.

Factors Influencing Seal Kit Selection

When selecting a hydraulic cylinder seal kit, several factors must be considered

1. Operating Conditions The working environment, temperature, and pressure levels directly affect seal performance. In high-temperature or high-pressure applications, specialized seals designed to withstand such conditions are necessary.

hydraulic cylinder seal kits

2. Fluid Compatibility The type of hydraulic fluid used is also crucial. Different fluids have varying properties that can deteriorate certain seal materials. It's essential to choose seals that are compatible with the hydraulic fluid to prevent swelling or hardening.

3. Application Requirements Different applications, whether in construction, manufacturing, or automotive industries, may require specific seal types and materials. Understanding the application ensures proper functionality and longevity.

Maintenance Best Practices

To maximize the lifespan of hydraulic cylinder seal kits, regular maintenance is vital. Here are some best practices

1. Routine Inspections Regularly inspect cylinders for signs of wear, such as fluid leaks or reduced performance. Early detection can prevent more serious issues.

2. Cleanliness Ensure the hydraulic system is free of contaminants. Dirt and debris can compromise seal integrity, leading to failures.

3. Timely Replacements Seals should be replaced as part of a scheduled maintenance routine. Waiting too long can lead to extensive damage to the hydraulic system.

4. Proper Installation Follow manufacturer guidelines for installing seal kits. Incorrect installation can lead to misalignment and premature wear.

In conclusion, hydraulic cylinder seal kits are vital components that ensure the efficiency and operational integrity of hydraulic systems. By investing in quality seals, understanding the factors influencing seal selection, and adhering to maintenance best practices, businesses can enhance the durability and performance of their hydraulic equipment. This proactive approach not only reduces downtime but also promotes safety and productivity in the workplace.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories