1 月 . 31, 2025 03:20 Back to list

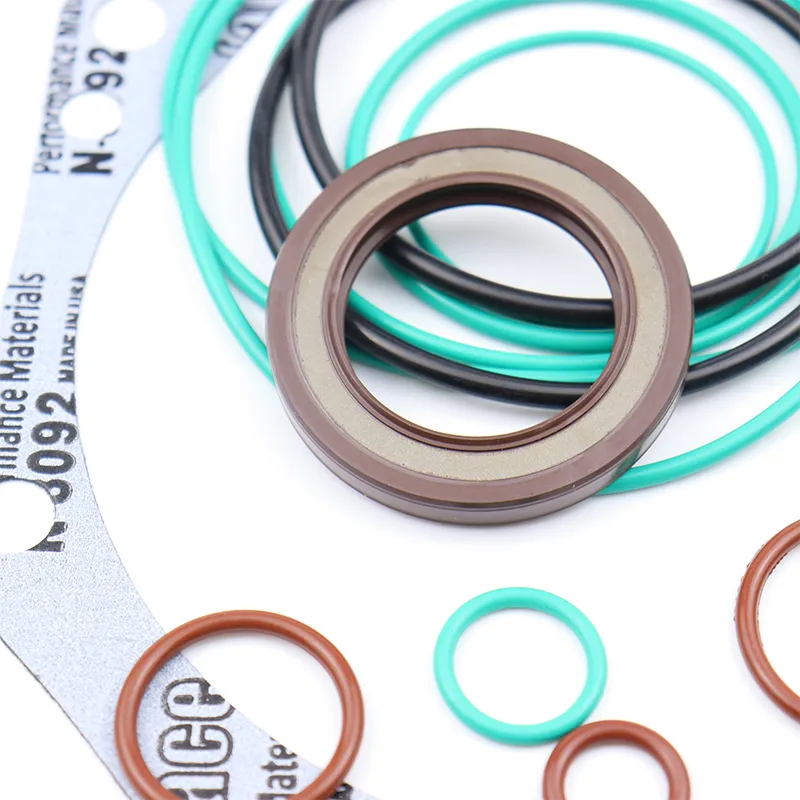

oil seal

Authority in the use of hydraulic cylinder rebuild kits comes through both knowledge transfer and practice. Experienced practitioners advise that users should undergo training or seek guidance from professionals when embarking on a rebuild project. This ensures a comprehensive understanding of the system's inner workings and the precise application of the kit's components. There is no substitute for the meticulous attention required during the disassembly and reassembly process, where each component placement can impact the entire system's functionality. The trustworthiness of hydraulic cylinder rebuild kits is enhanced by selecting products backed by warranties and customer support. Suppliers who provide detailed instructions and support are generally more reliable, offering users confidence in their purchases. Online reviews and testimonials can serve as additional assurances, highlighting the experiences of other users and providing insight into the kit's performance in real-world applications. Incorporating real user experiences into the decision-making process is invaluable. Forums and user groups dedicated to hydraulic systems frequently discuss rebuild kits, offering peer-driven reviews and sharing practical advice. These platforms serve as rich resources for troubleshooting and tips, fostering a collaborative environment among users. Ultimately, the effective use of hydraulic cylinder rebuild kits promises a cost-efficient and sustainable solution to hydraulic system maintenance. By fostering a comprehensive understanding of their application and benefits, users can significantly enhance machinery performance and extend its lifetime. Investing in quality rebuild kits and aligning efforts with experienced personnel or resources lays the groundwork for successful hydraulic system operation and longevity. Such diligence underscores the commitment to maintaining robust and reliable machinery, essential for any industry reliant on hydraulic power.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories