2 月 . 12, 2025 03:19 Back to list

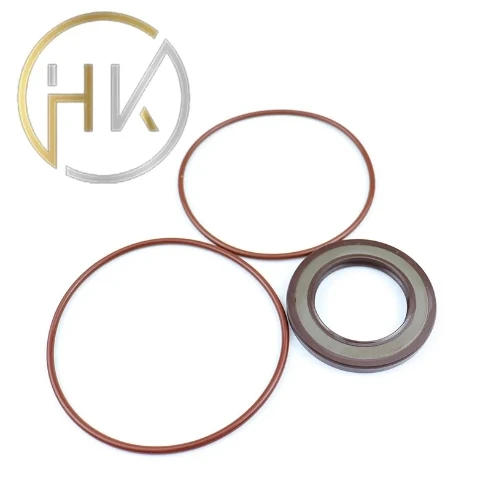

oil seal tcv

Supply chain dynamics and market demand further complicate pricing structures. Global economic shifts, raw material availability, and logistical considerations can create fluctuating costs that affect end-user pricing. In today's interconnected market, sourcing seals from reputable suppliers who have established stable logistical networks can mitigate price volatility and ensure consistent product availability. Engaging with authorized distributors or directly with manufacturers for bulk purchasing can also secure competitive pricing, making such partnerships a strategic priority for businesses reliant on hydraulic systems. For businesses and individuals, evaluating long-term costs against initial expenditure is crucial. Investing in higher-quality seals may seem onerous initially but can lead to substantial savings by minimizing maintenance costs, reducing the frequency of replacements, and enhancing overall system efficiency. Therefore, the true price of a hydraulic cylinder oil seal extends beyond mere procurement to encompass the broader financial implications of its performance and durability. Understanding these multifaceted aspects conveys both an expertise and attentiveness essential when discussing hydraulic cylinder oil seal pricing. By acknowledging the intricate relationship between material quality, manufacturing precision, customization needs, and supply chain factors, consumers can make informed purchasing decisions. Positioning oneself with a grasp of these nuances not only assures confidence in product selection but also reinforces trust in the integrity of the hydraulic system's operational foundation. Building this knowledge base, therefore, becomes a powerful tool in ensuring that hydraulic systems deliver peak performance, safeguarding not only investment but also operational continuity.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories