2 月 . 11, 2025 15:41 Back to list

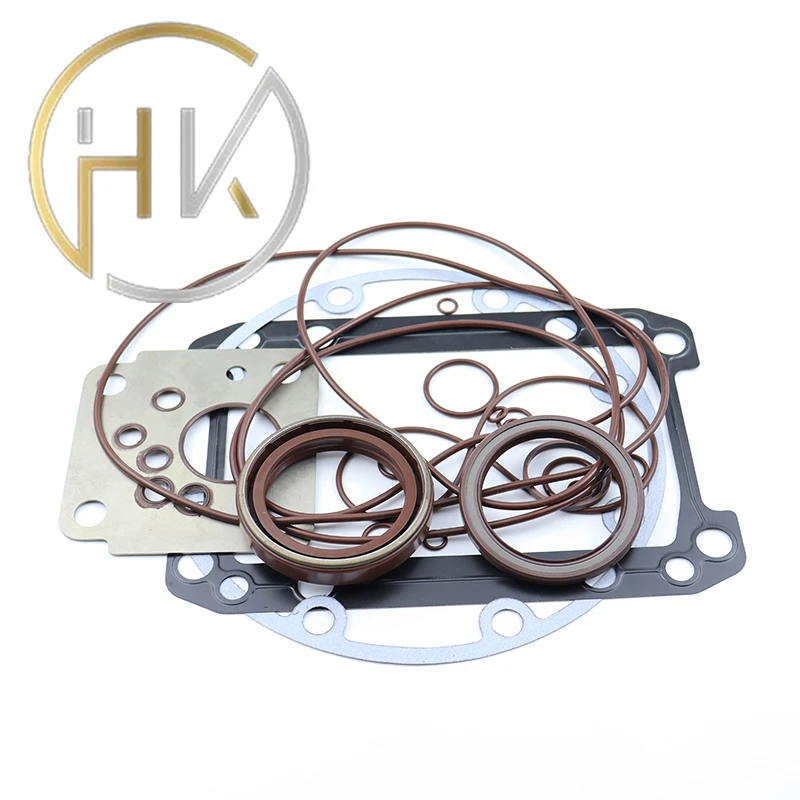

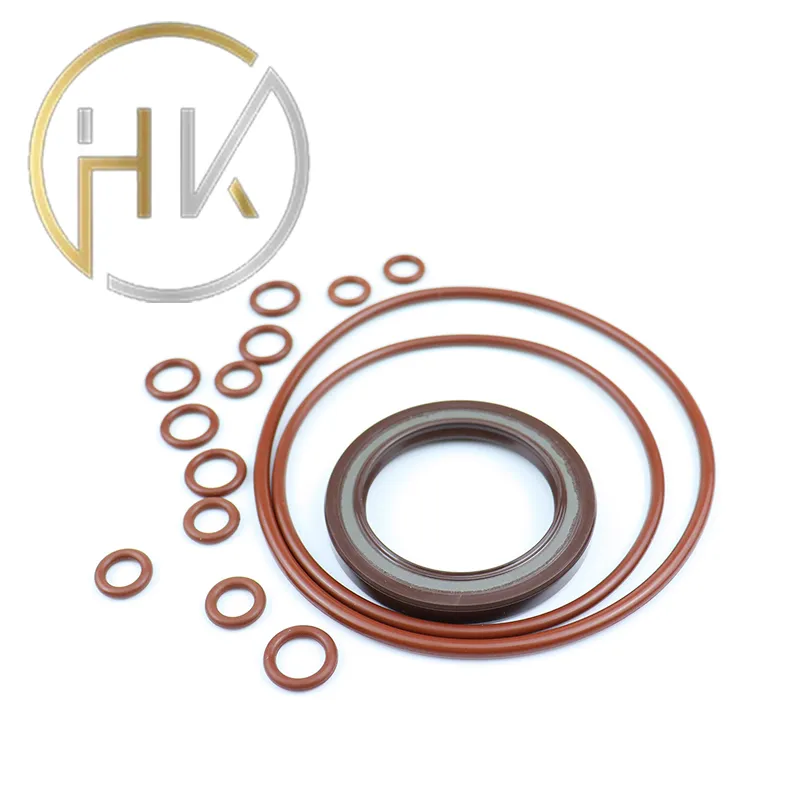

hydraulic cylinder oil seal kit

Trustworthiness in hydraulic seal selection is built through evidence-based results and proven reliability in field operations. Industry professionals often rely on seal kits from reputable manufacturers known for their stringent quality controls and innovations in seal design technology. These manufacturers often provide comprehensive guides and support to ensure their customers can make informed decisions when replacing or repairing hydraulic components. Furthermore, understanding hydraulic system dynamics and the latest trends in hydraulic technology can offer a competitive edge. For instance, with the push towards eco-friendly hydraulic fluids, more seal manufacturers are developing products that can function efficiently with biodegradable and fire-resistant fluid options available today. It's also prudent to consider kits that provide ease of installation and come with detailed instructions or support. This simplicity not only reduces downtime during maintenance but also significantly enhances system longevity through correct seal installation. Ultimately, a hydraulic cylinder oil seal kit should embody a blend of innovation, reliability, and tailored solutions that meet the specific demands of varied industrial applications. As an authoritative voice in hydraulic technology and tooling, selecting the right kit is about maintaining peak operational integrity while minimizing cost and ensuring system safety. By focusing on experience, expertise, authoritativeness, and trustworthiness, businesses can effectively optimize their hydraulic systems for a sustainable and productive future.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories