2 月 . 17, 2025 12:15 Back to list

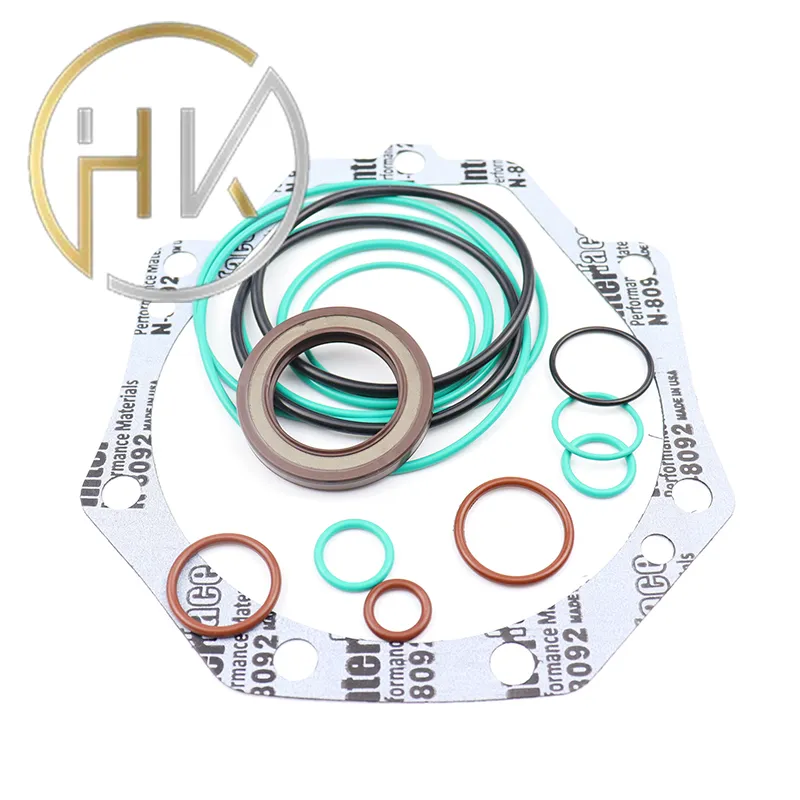

oil seal tcv

In terms of authority, some companies have established themselves as experts by investing in research and development. These organizations frequently publish studies and findings in industry journals, sharing knowledge on advancements in oil seal technology. This openness not only enhances their credibility but also propels the entire field forward, fostering a culture of continuous improvement. Practical experience also speaks volumes in this field. Feedback loops from users provide critical insights into how products perform under various conditions. Companies that prioritize customer feedback in their design process often produce products that are more aligned with user needs, proving once again that experience on the ground is invaluable. Lastly, in today’s digital age, establishing a trustworthy online presence is critical. Websites and content that offer in-depth technical specifications, user testimonials, and case studies contribute to a robust digital footprint. Combining this with SEO best practices ensures that when industry professionals seek reliable information or products online, your content surfaces first. Ultimately, the role of the hydraulic cylinder oil seal cannot be understated. Its proper selection and maintenance are vital for any hydraulic system's performance and longevity. Whether you are a machine operator, a procurement manager, or a maintenance engineer, a keen understanding of these seals, backed by a trust-based relationship with your supplier, can enhance operational efficiency and mitigate risks associated with hydraulic machinery failures.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories