11 月 . 01, 2024 09:34 Back to list

Effective Dust Seals for Hydraulic Cylinders to Enhance Performance and Longevity

Understanding Hydraulic Cylinder Dust Seals

Hydraulic systems are essential in various industries, providing the necessary power to machinery and equipment for effective operation. One vital component of hydraulic systems is the hydraulic cylinder, which converts hydraulic energy into mechanical energy. To ensure the longevity and functionality of hydraulic cylinders, dust seals play a crucial role.

A hydraulic cylinder dust seal is designed to prevent contaminants, such as dirt, dust, and debris, from entering the cylinder. These contaminants can lead to increased wear and tear of the cylinder's internal components, resulting in reduced efficiency and a higher likelihood of failure. Thus, the primary function of a dust seal is to maintain the cleanliness of the hydraulic system, enhancing the overall integrity and performance of the equipment.

Dust seals are typically made from materials that can withstand harsh environmental conditions while providing excellent resistance to abrasion and wear. Common materials include nitrile rubber, polyurethane, and PTFE (Teflon), each possessing unique properties suitable for different applications. For instance, nitrile rubber is known for its resistance to oils and fuels, making it an ideal choice in many hydraulic applications.

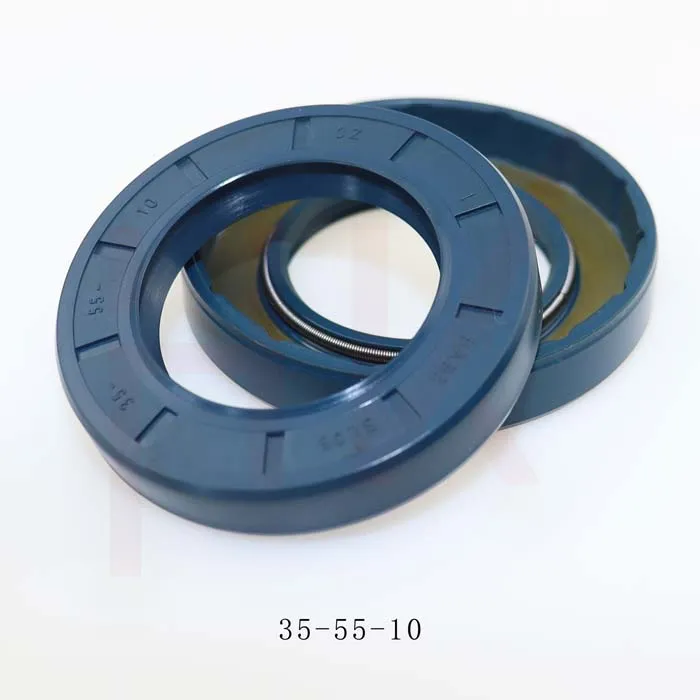

hydraulic cylinder dust seal

The design of dust seals can vary significantly depending on the specific requirements of the hydraulic system and operating environment. Some dust seals are simple lip seals, while others may incorporate additional features like springs or secondary sealing elements to provide better protection. The geometry of the dust seal has a direct impact on its performance and the ability to exclude contaminants; thus, careful consideration should be given to the design when selecting a dust seal for a hydraulic cylinder.

Regular maintenance and inspection of hydraulic dust seals are essential to ensure their effectiveness. Over time, seals can become worn or damaged due to exposure to extreme temperatures, pressure fluctuations, and abrasive particles. Implementing a routine maintenance schedule that includes checking and replacing dust seals when necessary can significantly extend the life of hydraulic cylinders and reduce the risk of costly downtime.

Incorporating dust seals into hydraulic systems not only protects the internal components of the cylinders but also enhances overall system efficiency. By keeping contaminants out, these seals play a vital role in ensuring that hydraulic fluids remain uncontaminated, thus maintaining optimal performance levels.

In conclusion, hydraulic cylinder dust seals are a critical aspect of hydraulic system design and maintenance. Understanding their importance, material choices, and design variations can help engineers and maintenance personnel select the appropriate seals for specific applications. By prioritizing the maintenance of dust seals, industries can ensure the reliability and longevity of their hydraulic systems, ultimately leading to improved productivity and reduced operational costs.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories