9 月 . 03, 2024 09:51 Back to list

hydraulic pump seals

Understanding Hydraulic Pump Seals Essential Components for Efficiency and Durability

Hydraulic pumps are vital components in various industries, delivering power through hydraulic fluid to facilitate machinery operation. One crucial aspect that ensures the efficient functioning of hydraulic pumps is the seals. Hydraulic pump seals play a significant role in preventing fluid leaks, maintaining pressure, and extending the lifespan of the equipment.

Hydraulic pump seals are designed to retain hydraulic fluid within the pump and prevent the ingress of contaminants. Without effective seals, the hydraulic system can suffer from fluid loss, resulting in a drop in pressure and efficiency. This can lead to greater energy consumption and increased operational costs. Moreover, fluid leaks can create a hazardous work environment and contribute to environmental pollution. Therefore, selecting high-quality seals is imperative for maintaining system integrity.

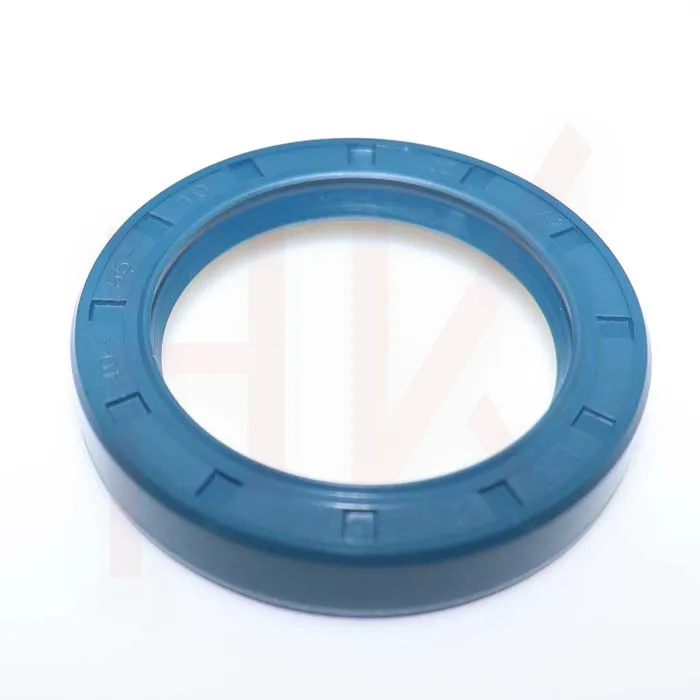

There are several types of seals used in hydraulic pumps, including O-rings, lip seals, and gland packing. Each type has its specific application and benefits. O-rings are commonly used due to their simple design and effectiveness in providing a reliable seal between static or dynamic surfaces. Lip seals, on the other hand, are designed to accommodate axial and radial movement, making them ideal for rotating components. Gland packing offers a traditional sealing method, primarily used in high-pressure applications, ensuring a tight seal around a shaft.

hydraulic pump seals

The material of hydraulic seals is also crucial. Common materials include nitrile rubber, polyurethane, and fluoroelastomers. Nitrile rubber is widely used due to its excellent resistance to petroleum-based fluids and moderate temperature range. Polyurethane seals offer superior abrasion resistance and are suitable for high-pressure applications. Fluoroelastomers, while more expensive, are used in extreme temperature environments and offer outstanding chemical resistance.

Maintaining hydraulic pump seals is essential to prevent premature failure. Regular inspection for wear and tear, contamination, and proper lubrication can enhance the performance and durability of the seals. Operators should also adhere to manufacturer guidelines regarding installation and replacement intervals to minimize risks associated with seal failure.

In conclusion, hydraulic pump seals are critical components that ensure the efficient operation of hydraulic systems. By preventing leaks, maintaining pressure, and protecting internal components from contamination, these seals contribute to the overall reliability and effectiveness of hydraulic equipment. Understanding the types, materials, and maintenance practices of hydraulic seals can lead to better performance, reduced downtime, and cost savings in various industrial applications.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories