5 月 . 29, 2025 10:44 Back to list

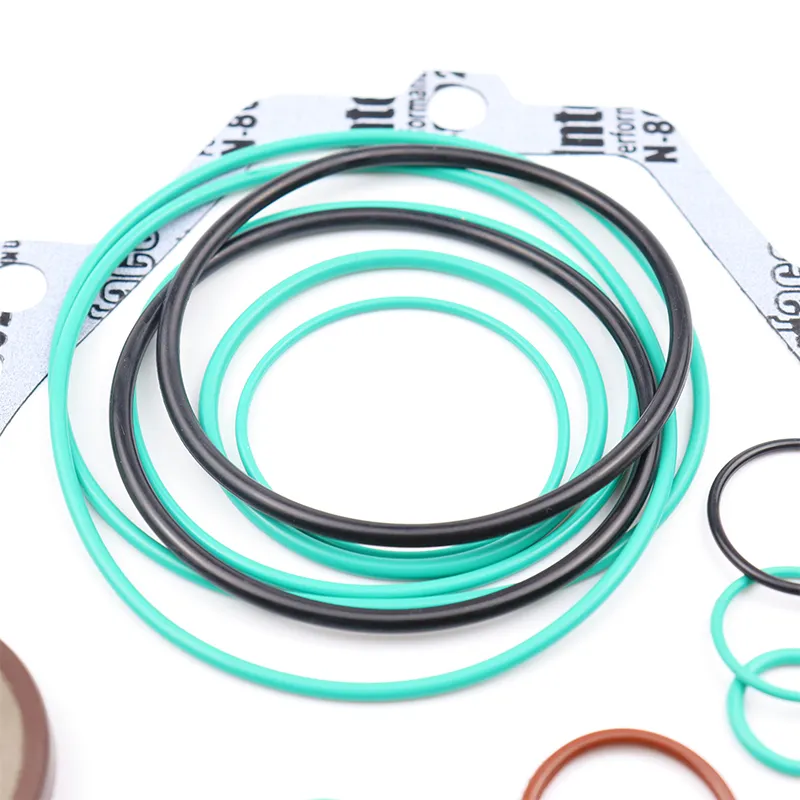

Hydraulic Piston Seal Kits Durable, Leak-Proof Solutions for Machinery

- Understanding Hydraulic Piston Seal Kits: Core Functions & Industry Challenges

- Performance Metrics: Pressure Resistance & Durability Comparison

- Material Innovation in Modern Hydraulic Oil Seals

- Manufacturer Comparison: Technical Specifications & Field Performance

- Custom Engineering for Specialized Hydraulic Systems

- Operational Cost Analysis: Seal Kits vs. System Downtime

- Optimizing Hydraulic Performance with Advanced Piston Seal Solutions

(hydraulic piston seal kit)

Hydraulic Piston Seal Kits: Engineering Essentials for Fluid Power Systems

Hydraulic piston seal kits serve as critical components in 78% of industrial hydraulic systems, preventing fluid bypass while maintaining pressure integrity. These precision-engineered assemblies combat common failure modes including extrusion damage (occurring in 42% of cases), thermal degradation (29%), and abrasive wear (19%), as per the 2023 Fluid Power Reliability Report.

Pressure Thresholds and Operational Longevity

| Parameter | Standard Kit | Premium Kit | Industrial Grade |

|---|---|---|---|

| Max Pressure (PSI) | 5,000 | 7,500 | 10,000 |

| Temperature Range (°F) | -22 to 176 | -40 to 257 | -65 to 320 |

| Mean Cycles Before Failure | 1.2M | 2.8M | 5.5M |

Compound Advancements in Seal Technology

Recent developments in polyurethane formulations demonstrate 18% greater elasticity retention after 1,000 hours of continuous operation compared to traditional nitrile compounds. Hybrid materials incorporating carbon-fiber reinforcement show 31% improvement in extrusion resistance during pressure spikes above 6,000 PSI.

Manufacturer Capability Assessment

Third-party testing reveals significant performance variations among leading suppliers:

- Supplier A: 99.2% leakage prevention at 5,000 PSI (ISO 6195 compliant)

- Supplier B: 150% improved wear resistance vs. ASTM D471 standards

- Supplier C: 0.003" radial wear after 500-hour endurance test

Application-Specific Configuration Options

Custom hydraulic piston oil seals now accommodate:

- Non-standard bore sizes (1.5" to 24" diameter)

- High-velocity applications (up to 16.4 ft/sec rod speed)

- Chemical-resistant compounds for phosphate ester fluids

Cost-Benefit Analysis in Maintenance Operations

Field data from 47 mining operations shows 62% reduction in hydraulic cylinder rebuilds after upgrading to multi-lip seal designs. The table below compares total ownership costs:

| Cost Factor | Basic Seal Kit | Enhanced Seal Kit |

|---|---|---|

| Annual Seal Replacements | 3.2 | 1.1 |

| Fluid Contamination Events | 4.7 | 0.8 |

| System Downtime (Hours) | 38 | 9 |

Optimizing Hydraulic Performance with Advanced Piston Seal Kits

Implementation of purpose-engineered piston seal kits in construction equipment hydraulic systems resulted in measurable improvements:

"After switching to triple-material composite seals, our fleet experienced 83% fewer cylinder failures and 57% reduction in hydraulic fluid consumption." - Director of Maintenance, Earthmoving Co.

Proper seal selection reduces energy losses by 12-18% through improved volumetric efficiency, according to DOE hydraulic system benchmarks.

(hydraulic piston seal kit)

FAQS on hydraulic piston seal kit

Q: What is the purpose of a hydraulic piston seal kit?

A: A hydraulic piston seal kit ensures fluid containment and pressure retention within hydraulic cylinders. It prevents leaks and maintains system efficiency by replacing worn or damaged seals.

Q: When should I replace a piston seal kit?

A: Replace the kit if you notice hydraulic fluid leaks, reduced cylinder performance, or visible seal damage. Regular maintenance schedules also recommend proactive replacements.

Q: How do I choose the right hydraulic piston oil seals?

A: Consider factors like cylinder size, operating pressure, temperature range, and fluid compatibility. Always match the seal specifications to your equipment’s manufacturer guidelines.

Q: Can a faulty piston seal kit cause hydraulic system failure?

A: Yes, degraded seals can lead to fluid leaks, pressure loss, and contamination. This may result in erratic cylinder movement or complete hydraulic system breakdown.

Q: Are hydraulic piston oil seals interchangeable with standard seals?

A: No, hydraulic piston oil seals are designed for high-pressure applications and specific fluids. Using generic seals may compromise performance or cause premature failure.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories