8 月 . 18, 2024 14:34 Back to list

Hydraulic Cylinder Repair Kits for Efficient Maintenance and Performance Improvement

Understanding Hydraulic Cylinder Kits Repair

Hydraulic cylinders are essential components in a variety of machinery and equipment, functioning to convert hydraulic energy into mechanical power. They are widely used across industries such as construction, manufacturing, and agriculture. However, like any mechanical component, hydraulic cylinders can experience wear and tear over time, leading to leaks, reduced efficiency, or complete failure. To ensure optimal performance and extend the operational life of hydraulic cylinders, regular maintenance and timely repairs using hydraulic cylinder kits are crucial.

What Are Hydraulic Cylinder Kits?

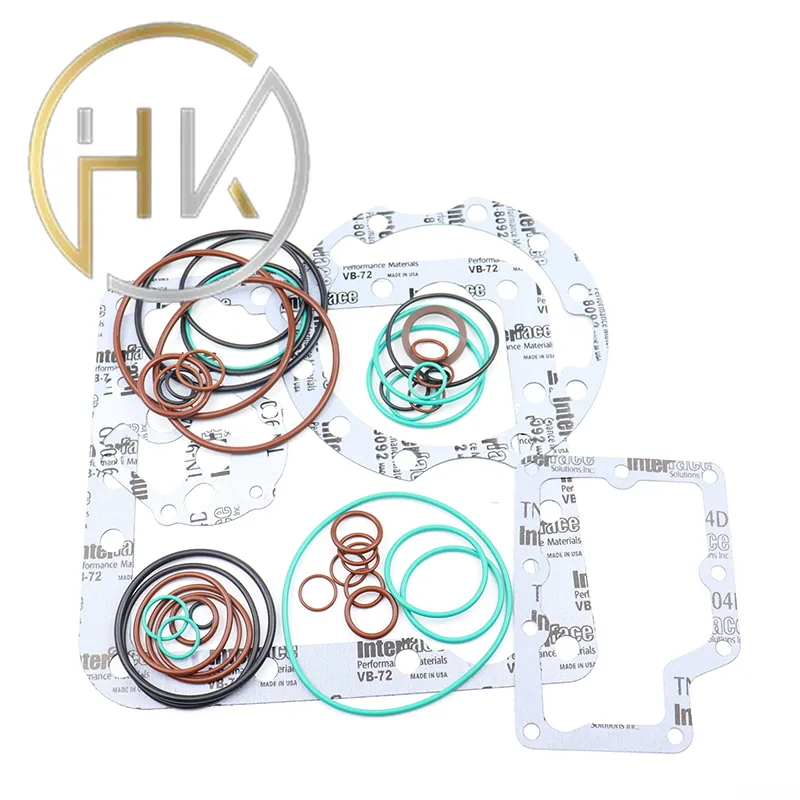

Hydraulic cylinder kits are comprehensive sets of components designed for the repair and maintenance of hydraulic cylinders. These kits typically include seals, O-rings, backup rings, bushings, and other essential parts that may be needed during the repair process. The exact contents of a hydraulic cylinder kit can vary depending on the specific model and manufacturer of the hydraulic cylinder, but the primary goal is to provide everything necessary to restore the cylinder to its optimal working condition.

Why Repair Hydraulic Cylinders?

There are several reasons why repairing hydraulic cylinders is often more beneficial than replacing them entirely

1. Cost-Effectiveness Purchasing a new hydraulic cylinder can be a significant investment. Repairing existing units using hydraulic cylinder kits is generally a more economical solution.

2. Reduced Downtime Replacing a hydraulic cylinder can lead to prolonged downtime. Repairs can often be completed quickly, allowing for a speedy return to normal operations.

3. Environmental Considerations Repairing rather than discarding hydraulic cylinders helps reduce waste and supports sustainable practices within the industry.

4. Maintaining Equipment Integrity Regular maintenance and timely repairs can help preserve the integrity of machinery, ensuring that equipment operates as intended.

hydraulic cylinder kits repair

The Repair Process

Repairing a hydraulic cylinder can be straightforward if done systematically

1. Disassembly The first step involves safely disassembling the hydraulic cylinder from the machinery. This process requires attention to detail, as it's important to note how components fit together.

2. Inspection Once disassembled, inspect all parts of the cylinder for wear, damage, or corrosion. Identifying the root cause of issues, such as leaks, will help in selecting the right components from the hydraulic cylinder kit for replacement.

3. Replacement Using the parts from the hydraulic cylinder kit, replace worn or damaged components like seals and O-rings. It's crucial to ensure that all parts fit properly and are compatible with the specific model of the cylinder.

4. Reassembly After the replacement parts have been installed, carefully reassemble the hydraulic cylinder, ensuring that all components are correctly aligned and secure.

5. Testing Finally, the repaired hydraulic cylinder should be tested under pressure to ensure it operates properly without leaks or malfunctions.

Conclusion

Maintaining hydraulic cylinders through the use of hydraulic cylinder kits is an effective strategy that ensures operational efficiency and longevity. Regular repairs not only save costs but also contribute to a more sustainable approach to machinery maintenance. For businesses that rely heavily on hydraulic systems, investing in quality hydraulic cylinder kits and adhering to a regular maintenance schedule can lead to significant benefits, including improved productivity and reduced risk of unexpected breakdowns. By understanding the importance of hydraulic cylinder kits repair, operators can ensure their machinery remains reliable and efficient for years to come.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories