2 月 . 17, 2025 15:44 Back to list

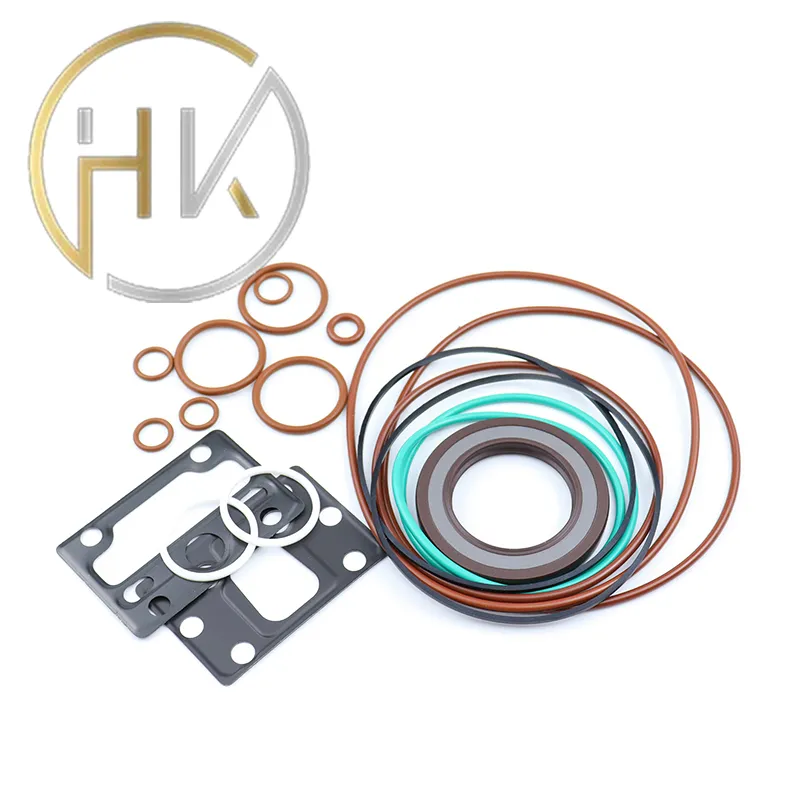

hub seal

Real-world experience shows that improper installation of hub seals can lead to premature failure. Such failures could cause severe damage extending beyond just the bearings to affect the spindle and axle, resulting in costly repairs or replacements. Therefore, the installation process requires careful attention to detail, often using specialized tools to prevent damage during insertion. Additionally, proper lubrication during installation cannot be overlooked, as it ensures the smooth operation of the seal and prolongs its life. Fleet operators have shared experiences where upgrading to higher-quality hub seals resulted in noticeable reductions in maintenance costs and downtime. These seals, featuring advanced compounds or coatings, offer lower friction coefficients, reducing the stress on associated components. For long-haul truckers, this translates into fewer roadside breakdowns, saving time and increasing productivity, thereby affirming the trust placed in these high-performance components. Trustworthiness in the hub seal market is further provided by customer testimonials and reviews that give potential buyers confidence in their purchase decisions. Manufacturers often provide extended warranties on these seals, ensuring that any defects will be addressed promptly—another indication of the durability and reliability buyers can expect. In conclusion, hub seals are a vital component that ensures the optimal and efficient performance of vehicles, particularly those involved in heavy-duty applications. With the combination of material science, precision engineering, and industry-leading manufacturing processes, these seals deliver the expertise and reliability needed to keep wheels turning safely. The authoritative practices of manufacturers and the positive feedback from experienced users bolster trust in these essential products, ensuring they remain an indispensable part of the machinery they serve.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories