12 月 . 06, 2024 01:54 Back to list

hub rubber seal

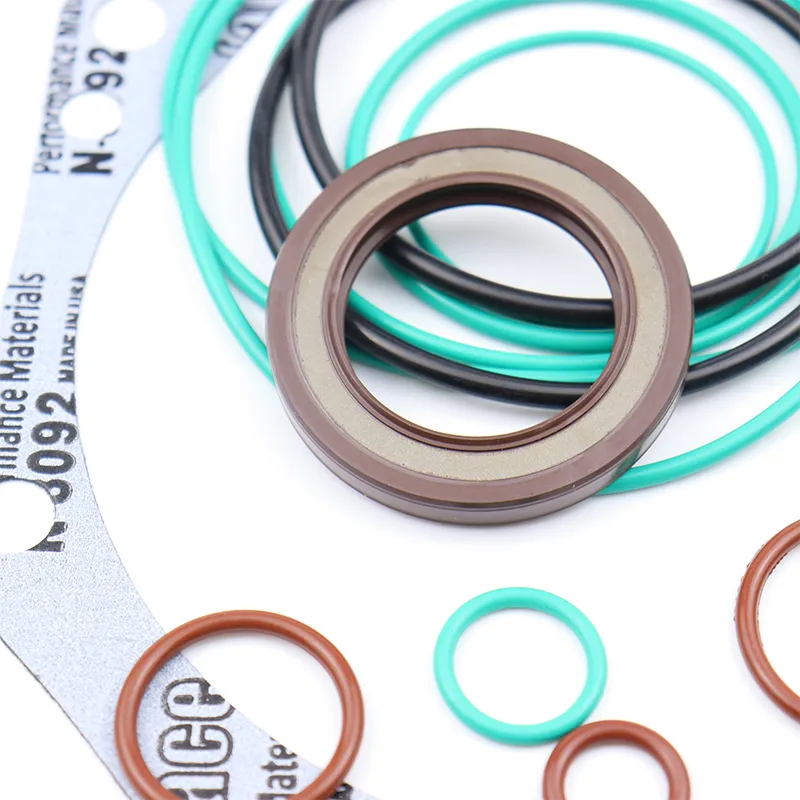

The Importance of Hub Rubber Seals in Modern Machinery

In today's fast-paced industrial landscape, the efficiency of machinery plays a crucial role in overall productivity. One often overlooked but vital component in the operation of various machines, particularly in automotive and industrial contexts, is the hub rubber seal. This component serves a multifaceted purpose, contributing to both the performance and longevity of equipment.

Understanding Hub Rubber Seals

A hub rubber seal is designed to fit securely around the wheel hub or gearbox, creating a barrier that prevents the ingress of dust, water, and other contaminants. It is typically made from high-quality rubber materials, which provide flexibility and durability under various working conditions. These seals are engineered to withstand significant temperature fluctuations and mechanical stress, making them an essential component in environments where equipment is regularly subjected to harsh conditions.

Key Functions of Hub Rubber Seals

1. Contaminant Prevention One of the primary functions of a hub rubber seal is to keep out dirt, mud, and moisture. When contaminants penetrate the machinery through compromised seals, they can cause wear and tear on moving parts, ultimately leading to equipment failure. By providing a reliable barrier, hub rubber seals help maintain the integrity of critical components, ensuring smooth operation.

2. Lubrication Retention Alongside preventing contaminants from entering, hub rubber seals help retain lubricants within the system. Proper lubrication is essential for reducing friction and wear on mechanical parts. Without an effective seal, lubricants can leak out, leading to insufficient lubrication and, in severe cases, complete mechanical breakdown.

hub rubber seal

3. Vibration Dampening Hub rubber seals also play a role in absorbing vibrations. During operation, machinery can be subject to various forces that cause vibrations. The rubber material of the seal can help mitigate some of these vibrations, reducing wear on the machinery and providing a smoother operational experience.

4. Noise Reduction Similarly, the design of hub rubber seals can contribute to noise reduction. By preventing the entry of dust and other particles, which can create unpleasant sounds during operation, these seals help maintain a quieter working environment. This is particularly important in settings where noise levels must be kept to a minimum for safety and comfort.

Quality and Maintenance Considerations

Choosing high-quality hub rubber seals is essential for ensuring the longevity and efficiency of machinery. It is vital to select seals that are specifically designed for the application at hand, as variations in size, shape, and material can significantly impact performance. Regular inspections and maintenance of seals should also be part of any preventative strategy. By monitoring the condition of these seals and replacing them when necessary, businesses can avoid costly downtime and repairs caused by seal failure.

Conclusion

In summary, hub rubber seals are critical components in various machinery, providing essential protection against contaminants, helping retain lubrication, dampening vibrations, and reducing noise. While they may be small and often taken for granted, their role in maintaining the efficiency and longevity of industrial and automotive operations is immense. Investing in high-quality hub rubber seals and maintaining them properly can lead to enhanced performance and considerable savings in the long run. As industries continue to evolve, focusing on the integrity of each component, including seemingly minor elements like rubber seals, will be essential in driving progress and innovation.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories