2 月 . 17, 2025 16:37 Back to list

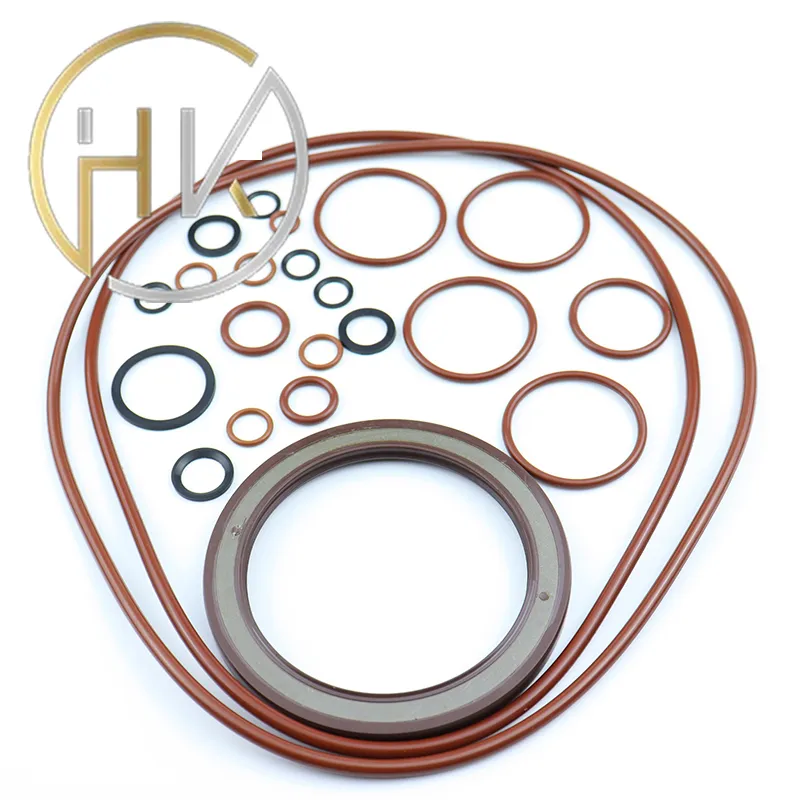

hub grease seal

In terms of product selection, trustworthiness is critical. Opting for products from reputable manufacturers known for quality and durability often results in better performance. Such manufacturers typically invest in research and development, ensuring their products meet, if not exceed, the rigorous demands of modern automotive requirements. Furthermore, authoritative reviews and ratings from certified mechanics and automotive professionals provide valuable insights into product performance. Analyzing these reviews can help consumers make informed decisions based on authentic experiences from industry authorities. Lastly, understanding the environmental and operational conditions in which the vehicle operates enables a tailored approach to choosing the right hub grease seal. Vehicles subjected to heavy loads or frequent off-road conditions may require seals with higher resilience and protective features compared to those driven under regular city conditions. Aligning the selection criteria with these operational parameters underscores the expertise and knowledge necessary for effective vehicle maintenance. Choosing and maintaining the correct hub grease seal extends beyond a simple purchase; it represents a comprehensive understanding of vehicle care and maintenance. Combining experience, expertise, authoritativeness, and trustworthiness not only assures optimal vehicle performance but also demonstrates a commitment to sustainable and informed automotive practices.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories