10 月 . 12, 2024 00:42 Back to list

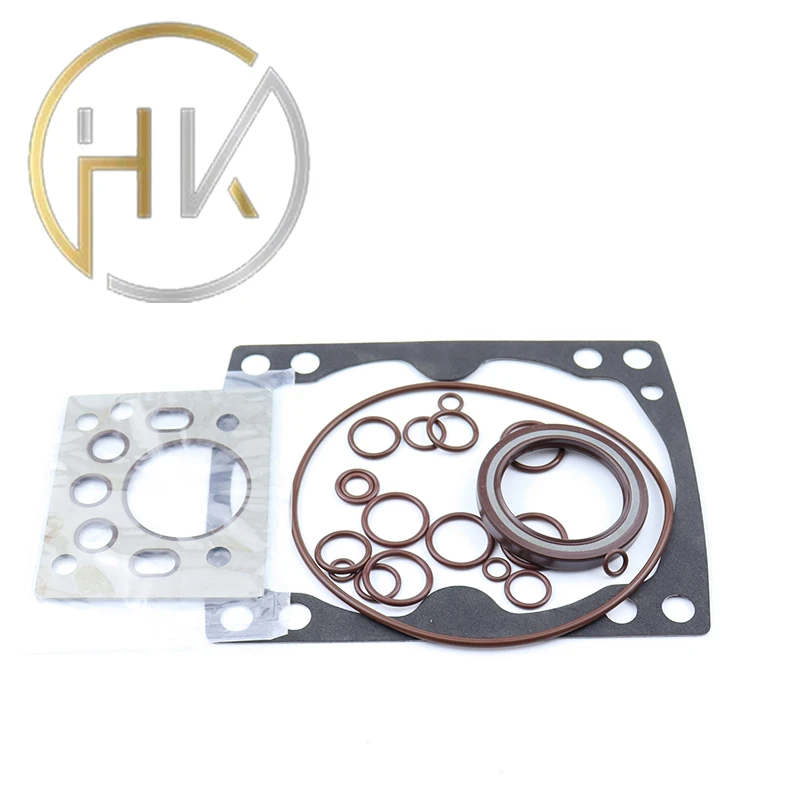

hub grease seal

Understanding Hub Grease Seals Importance and Functionality

In the world of automotive and machinery maintenance, the hub grease seal is often an overlooked yet crucial component. These seals play a vital role in ensuring the longevity and efficiency of various systems, particularly in vehicles and other equipment that rely on rotating components.

A hub grease seal is designed to prevent grease from leaking out of the hub assembly while simultaneously keeping dirt, water, and other contaminants from entering. This dual function is essential because grease serves as a lubricant for bearings and other moving parts, reducing friction and wear. When grease escapes or foreign particles infiltrate, the risk of damage to the bearings increases significantly, potentially leading to premature failure and costly repairs.

The design of hub grease seals typically involves a flexible rubber or synthetic material that can accommodate the dynamic nature of hub assemblies

. These seals are engineered to form a tight barrier around the rotating axle and other components, ensuring that the lubrication remains contained. The effective sealing mechanism not only enhances the lifespan of the grease itself but also maintains optimal performance in terms of smooth operation and heat dissipation.hub grease seal

Choosing the right hub grease seal is paramount for any maintenance or repair task. Factors such as the type of vehicle, the specific application, and the operating environment must all be considered. For example, vehicles subjected to harsh conditions—like off-road environments or extreme temperatures—may require specialized seals that can withstand these challenges without compromising integrity.

Installation of hub grease seals requires precision and care. An improperly installed seal can lead to sealing failures, which might result in grease leaks or contamination ingress. Therefore, it is always recommended to follow the manufacturer’s guidelines or seek professional assistance during installation.

Regular maintenance checks that include inspecting the condition of hub grease seals can save vehicle owners from unforeseen breakdowns. Signs of wear, such as cracks or deformation in the seal material, should not be ignored. If a seal is suspected to be compromised, replacing it promptly can prevent further damage and enhance overall system reliability.

In summary, hub grease seals are a fundamental yet often underappreciated component in the functioning of various mechanical systems. Their role in preventing grease loss and contamination is vital for protecting bearings and ensuring the smooth operation of moving parts. When maintaining vehicles or machinery, one should not overlook the importance of these seals. Regular inspections and using the right type of seal can contribute significantly to the longevity and efficiency of the equipment, ultimately saving time and reducing costs associated with repairs and replacements. Whether you are a DIY enthusiast or a professional technician, understanding and prioritizing hub grease seals can make a significant difference in your maintenance routine.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories