12 月 . 03, 2024 18:05 Back to list

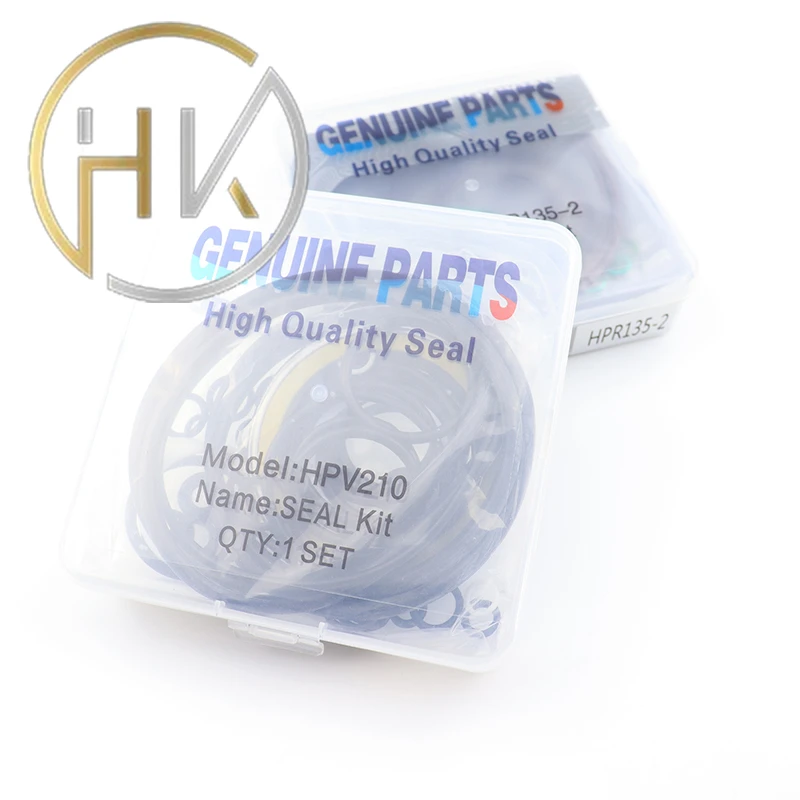

hub bearing seal

Understanding Hub Bearing Seals Essential Components for Vehicle Performance

Hub bearing seals are critical components in the automotive industry, designed to protect hub bearings from contaminants and retain lubrication. As vehicles have evolved, so too have the technologies and materials used for these seals, enhancing the overall performance, longevity, and reliability of vehicles. In this article, we will explore the role, types, materials, and maintenance of hub bearing seals.

The Role of Hub Bearing Seals

At the heart of a vehicle's wheel assembly is the hub bearing, which supports the weight of the vehicle and allows the wheels to rotate smoothly. Hub bearing seals play a crucial role in ensuring that these bearings operate effectively. Their primary functions include

1. Contamination Prevention Hub bearing seals keep dirt, dust, mud, and water from infiltrating the bearing assembly. Contaminants can lead to premature wear, increased friction, and ultimately, bearing failure.

2. Lubrication Retention These seals help retain the grease or oil within the bearing. Proper lubrication is essential for minimizing friction and heat generation, which can compromise the integrity of the bearing.

3. Pressure Management As the vehicle operates, temperature changes can create pressure differentials. Hub bearing seals are designed to accommodate these pressure changes, ensuring that the bearing remains properly lubricated and protected.

Types of Hub Bearing Seals

There are various types of hub bearing seals available, each designed for specific applications and requirements. Some common types include

1. Lip Seals These seals generally feature a flexible lip that makes contact with the shaft or housing. They provide excellent sealing capabilities against oil and dirt, making them suitable for various automotive applications.

2. Double-lip Seals These seals have two sealing edges, providing enhanced protection against contamination. They are often used in more demanding applications where exposure to harsh environments is likely.

3. Labyrinth Seals Instead of a traditional sealing lip, labyrinth seals use a series of grooves and channels to create a tortuous path that contaminants must navigate. This design is effective in preventing the entry of contaminants while allowing for some ventilation.

4. O-Ring Seals An O-ring seal can be employed in hub assemblies to ensure a tight fit and effective sealing against liquids and contaminants. They are often used in conjunction with other seal types for added protection.

hub bearing seal

Materials Used in Hub Bearing Seals

The materials used in hub bearing seals are crucial to their durability and performance. Common materials include

1. Rubber Commonly used for lip seals, rubber offers flexibility and resilience. Different compounds, such as nitrile or silicone, are chosen based on temperature and chemical exposure.

2. Polymer Composites Advanced polymer materials can provide superior strength and resistance to wear and chemicals, making them suitable for modern applications.

3. Metal In some cases, metal components are integrated into seals to enhance structural integrity and improve resistance to extreme conditions.

Maintenance and Replacement

Regular maintenance of hub bearing seals is essential for ensuring the longevity of the bearings and overall vehicle performance. Here are a few tips

1. Visual Inspections During routine vehicle inspections, look for signs of wear or damage to the seals. Cracks, tears, or distortions are indicators that replacement may be necessary.

2. Lubrication Checks Ensure that the hub bearings are adequately lubricated. Low lubrication levels can lead to increased friction and premature seal degradation.

3. Replacement If seals are found to be damaged or worn, they should be replaced promptly to prevent further damage to the hub bearing assembly.

Conclusion

Hub bearing seals play a vital role in the smooth operation and longevity of vehicle wheel assemblies. Understanding their functions, types, and maintenance is essential for vehicle owners and technicians alike. By investing in high-quality seals and adhering to maintenance best practices, one can significantly enhance vehicle performance and durability on the road. In an era of increasing vehicle complexity, paying attention to such integral components can prevent costly repairs and ensure a safe driving experience.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories