2 月 . 02, 2025 02:05 Back to list

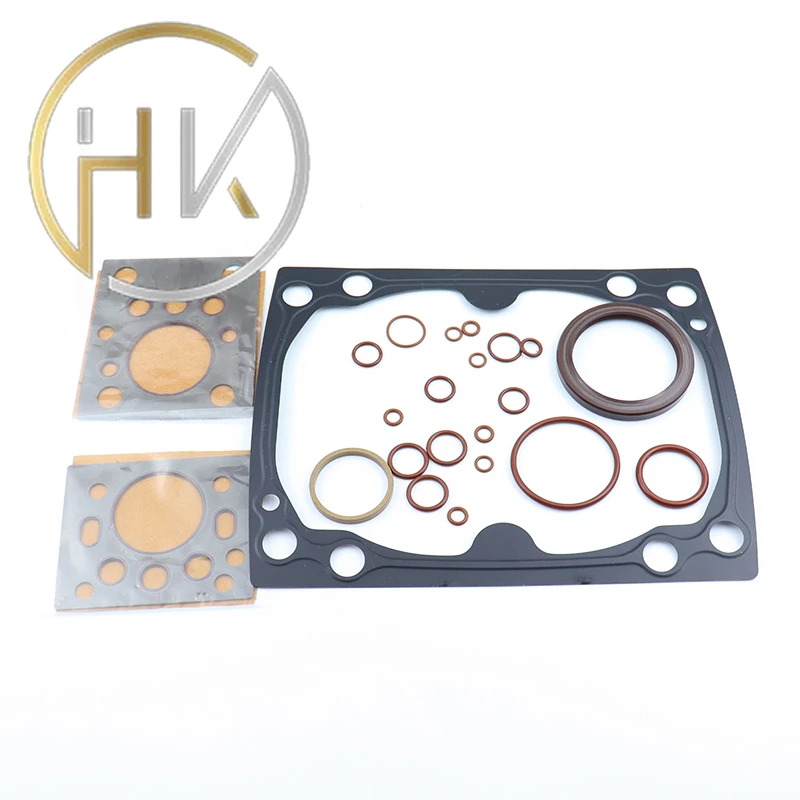

high temp oil seal

An authoritative approach entails consulting with suppliers or manufacturers with a proven track record in producing high-quality O-rings. Engaging with established companies that adhere to stringent manufacturing standards and possess relevant certifications like ISO 9001 ensures that you receive products that meet critical safety and performance criteria. Additionally, these manufacturers often provide detailed datasheets and customer support, offering valuable insights into the specifications and best uses of their products, reinforcing their trustworthiness. To guarantee trustworthiness in your purchase, thoroughly review user testimonials and case studies regarding the O-rings you're interested in. Real-world reviews from industries similar to yours can shed light on the performance and reliability of specific products. Building trust also involves verifying the brand's reputation through third-party assessments or industry awards, indicating the manufacturer's commitment to quality and innovation. In conclusion, selecting a high-quality high temperature O-ring kit involves a combination of understanding material properties, leveraging expert advice, consulting with reputable suppliers, and reviewing user feedback. By focusing on these four pillars – experience, expertise, authoritativeness, and trustworthiness – you can ensure your operations benefit from the best sealing solutions available, minimizing risks and optimizing performance. This holistic approach not only mitigates the chances of equipment failure but also contributes to the overall safety and cost-effectiveness of your industrial processes.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories