9 月 . 29, 2024 01:03 Back to list

High Temperature O-Ring Kits for Reliable Sealing Solutions in Extreme Conditions

The Importance of High-Temperature O-Ring Kits in Industrial Applications

In the vast realm of engineering and manufacturing, the reliability and efficiency of machinery are paramount. Among the myriad of components that play a crucial role in ensuring optimal performance is the O-ring—a simple yet vital element in various systems. Particularly, high-temperature O-ring kits are indispensable in applications exposed to extreme thermal conditions. This article delves into the significance of high-temperature O-ring kits, their materials, applications, and maintenance considerations.

Understanding O-Rings

O-rings are circular seals often made from elastic materials that serve to prevent the leakage of fluids or gases in mechanical systems. Their design allows them to be compressed between two or more parts, providing a tight seal that can withstand pressure. While standard O-rings are suitable for moderate temperature ranges, specialized versions are required for high-temperature environments, such as those found in aerospace, automotive, and industrial machinery.

Materials for High-Temperature O-Rings

The effectiveness of high-temperature O-rings largely depends on the materials from which they are made. Unlike standard rubber compounds, which can degrade when exposed to excessive heat, high-temperature O-rings are crafted from advanced materials designed for durability and resilience. Some of the most common materials include

1. Fluoroelastomers (FKM) Known for their excellent resistance to high temperatures (up to 250°C or 482°F) and chemical exposure. FKM O-rings are commonly used in automotive and aerospace applications.

2. Silicone Withstanding temperatures from -60°C to 230°C (-76°F to 446°F), silicone O-rings are ideal for applications requiring flexibility and resilience, such as medical devices and food processing equipment.

3. Polyurethane Highly resistant to wear and abrasion, polyurethane O-rings can function effectively at temperatures up to 90°C (194°F) and are used in a variety of industrial applications.

4. PTFE (Teflon) While not an elastomer, PTFE is used in O-ring applications where extreme heat and chemical resistance are necessary. PTFE O-rings can endure temperatures up to 260°C (500°F) and are often employed in the pharmaceutical and chemical industries.

Applications of High-Temperature O-Ring Kits

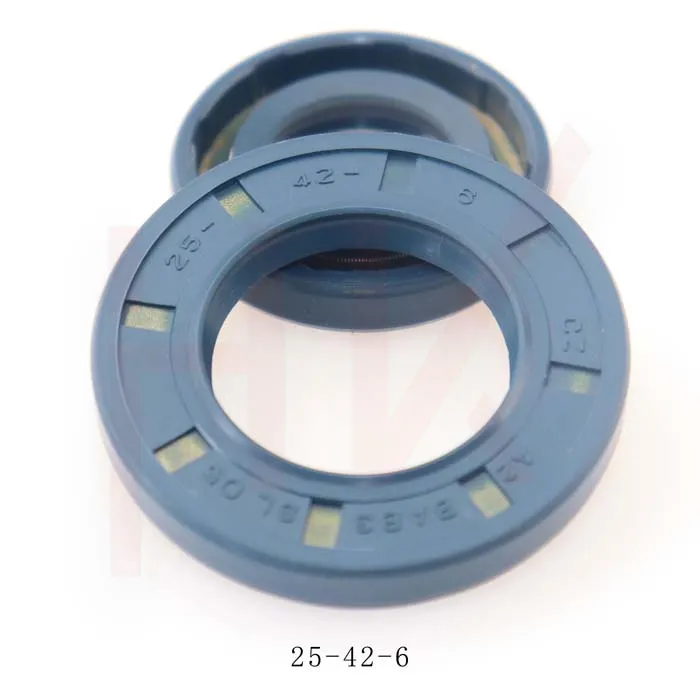

high temperature o ring kit

High-temperature O-ring kits are crucial in various sectors. Here are some prominent applications

- Aerospace In aircraft engines and systems where temperatures can soar during operation, high-temperature O-ring kits ensure safe and efficient sealing, preventing leaks of fuel and hydraulic fluids.

- Automotive Engines and transmissions generate significant heat. High-temperature O-rings are utilized to maintain the integrity of seals in these critical components, enhancing performance and longevity.

- Oil and Gas Equipment used in drilling and extraction must withstand extreme temperatures and pressures. High-temperature O-rings help maintain the functionality of valves and other vital components.

- Food Processing Ensuring hygiene and safety is critical in food manufacturing. High-temperature silicone O-ring kits are widely used in steam cleaning and sterilization processes.

Maintenance and Replacement

The performance of O-rings can degrade over time, especially under high-temperature conditions. Regular inspection and maintenance of O-rings are essential to avoid catastrophic failures. Signs that O-rings may need replacement include visible wear, hardening, cracking, or loss of elasticity.

When replacing O-rings, it is vital to select the appropriate material and size to ensure a proper fit and seal. Using high-quality O-ring kits from reputable manufacturers can significantly enhance the longevity and reliability of machinery.

Conclusion

In conclusion, high-temperature O-ring kits are integral to the functionality and safety of various industrial applications. Their ability to withstand extreme thermal conditions makes them a crucial component in modern engineering. With advancements in material technology, the reliability of these sealing solutions continues to improve, supporting the demands of constantly evolving industries. Investing in high-quality high-temperature O-ring kits and prioritizing regular maintenance not only enhances operational efficiency but also significantly reduces the risk of leaks and failures in critical systems.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories