2 月 . 16, 2025 15:49 Back to list

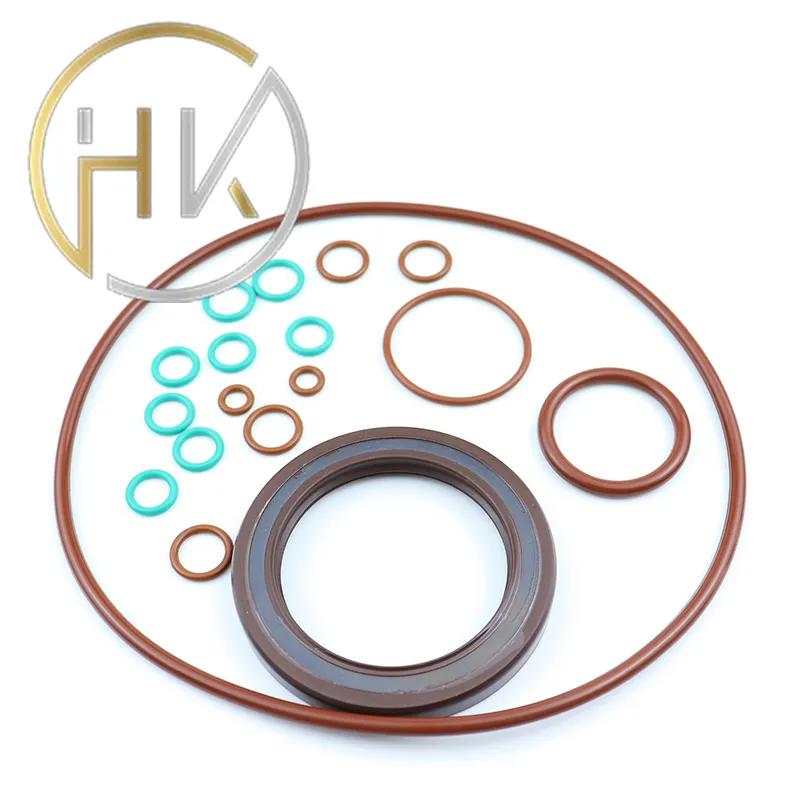

rotary oil seals

The installation of high-pressure rotary shaft seals demands a careful approach. During installations, any damage to the seal surface can compromise functionality. It is essential that the seating surfaces are spotless and free of nicks or scratches. Installing tools such as tapered sleeves or bullet tools can facilitate smooth installation, minimizing the risk of damaging the primary lip or secondary components. Moreover, regular maintenance of these seals significantly extends their lifespan. Routine inspection is crucial, assessing for signs of wear, such as hardening, cracking, or excessive lip wear. Lubrication is another critical element; using incompatible or inadequate lubricants can result in increased friction, leading to seal failure. It is advisable to adhere to manufacturer recommendations regarding both the type and volume of lubricant to be applied. The impact of technological advancements cannot be overstated in the realm of high-pressure rotary shaft seals. Innovations in materials science continue to push the boundaries of what these seals can achieve, ensuring they remain at the forefront of machinery reliability. As industries demand higher efficiencies and operational safety, the developments in seal technology provide an essential component to achieving these goals. The expertise involved in the engineering and application of these seals imparts a level of authority and trustworthiness essential for industrial leaders. Collaboration with experienced manufacturers or consulting with seal experts can provide valuable insights, ensuring the correct specification and installation. They bring a comprehensive understanding of material properties, loading conditions, and fluid dynamics that is vital for the optimal operation of high-pressure systems. In conclusion, high-pressure rotary shaft seals are more than just machine components; they are keystones in industrial operations that demand reliability and exceptional performance. By leveraging the right materials, designs, and installation practices, industries can achieve unparalleled efficiency and operational security. For those in charge of maintaining industrial equipment under extreme conditions, understanding these seals is not just beneficial—it is pivotal to success.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories