10 月 . 09, 2024 09:49 Back to list

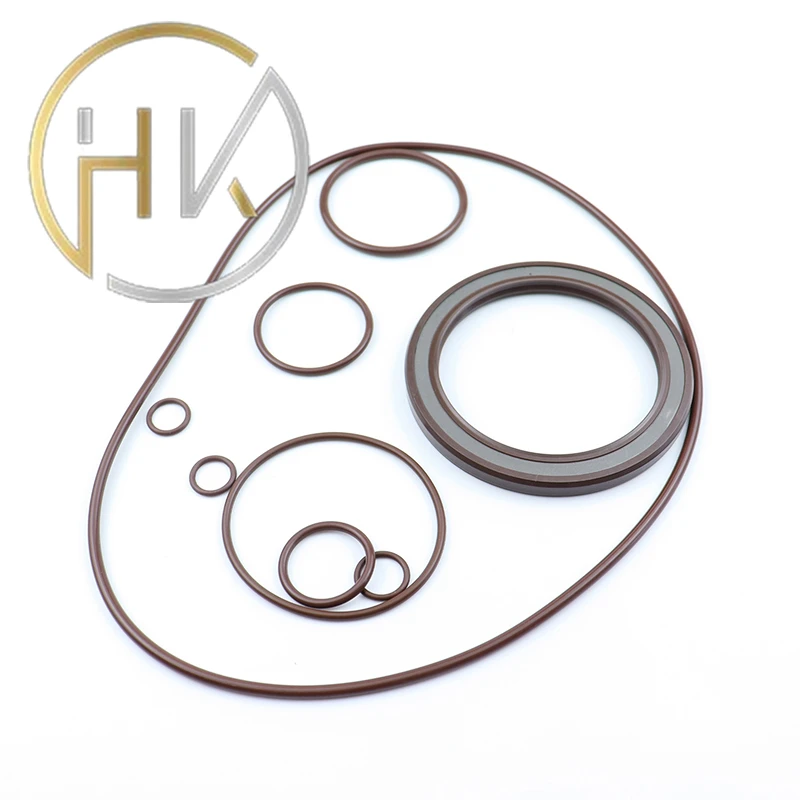

high pressure rotary shaft seals

High Pressure Rotary Shaft Seals An Overview

Rotary shaft seals, commonly known as oil seals or rotary seals, are critical components in various industrial applications, particularly where high-pressure conditions are a factor. These seals are designed to prevent the leakage of lubricants while also keeping contaminants out of the system. This article delves into the functionality, types, and applications of high-pressure rotary shaft seals and their importance in maintaining operational efficiency and equipment longevity.

Functionality of High Pressure Rotary Shaft Seals

High-pressure rotary shaft seals function by providing a barrier between rotating and stationary components, typically in a dynamic environment. They are essential for retaining lubricants and preventing fluid loss, which can lead to increased operational costs and potential equipment failure. The seals work on the principle of creating a thin film of lubricant, which reduces friction, thereby extending the lifespan of both the seal and the component it protects.

These seals are engineered to withstand pressures that can reach up to several hundred bars, making them suitable for a wide range of applications. The effectiveness of high-pressure seals is largely dependent on their materials, design, and installation methodology. The seal should not only prevent leakage but also accommodate thermal expansions and contractions that occur during operation.

Types of High Pressure Rotary Shaft Seals

There are several types of rotary shaft seals specifically designed for high-pressure applications

1. Lip Seals These include a flexible lip that makes contact with the shaft as it rotates. Lip seals are commonly used due to their simple design and effectiveness in sealing against oil and other fluids.

2. Dual-Lip Seals Featuring two sealing lips, dual-lip seals provide enhanced protection against leakage and contamination. This design is particularly useful in environments where the risk of dirt or dust intrusion is high.

3. Mechanical Seals Often used in pumps and compressors, mechanical seals provide a robust solution for high-pressure applications. They use two flat faces to create a seal and are typically combined with springs to maintain contact with the rotating shaft.

high pressure rotary shaft seals

4. Stuffing Box This type incorporates packing material into a housing around the shaft. While more traditional, stuffing boxes can effectively manage high-pressure scenarios, especially in larger machinery.

Applications of High Pressure Rotary Shaft Seals

High-pressure rotary shaft seals are widely used in various industries, including

- Hydraulics In hydraulic systems, seals maintain fluid integrity under high pressure, ensuring efficient machine operation.

- Aerospace They are crucial in aircraft engines and hydraulic systems, where they prevent fluid leaks that could lead to catastrophic failures.

- Oil and Gas The exploration and extraction of oil and gas depend heavily on seals due to the extreme pressures encountered at depths.

- Manufacturing Heavy machinery in manufacturing sectors uses rotary seals to ensure uninterrupted operations and minimize downtime.

Importance of High Pressure Rotary Shaft Seals

The importance of high-pressure rotary shaft seals extends beyond mere functionality. They play a vital role in enhancing the efficiency of machines, reducing maintenance costs, and prolonging equipment life. By preventing fluid loss and contamination ingress, these seals contribute to maintaining optimal operational conditions, which is essential in high-stakes environments.

In conclusion, high-pressure rotary shaft seals are indispensable components in various industrial applications. Their ability to operate effectively under extreme conditions makes them crucial for ensuring the reliability and efficiency of machinery. As industries continue to evolve, the demand for advanced sealing solutions will grow, pushing the development of more innovative and resilient seal designs to meet the challenges of modern engineering.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories