1 月 . 20, 2025 03:52 Back to list

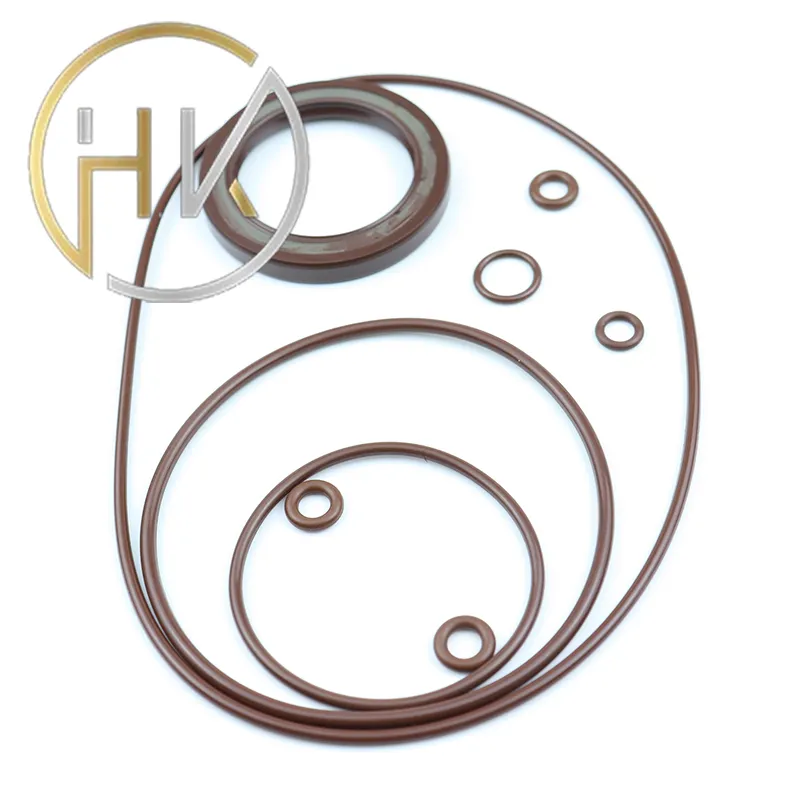

185*205*11 Rubber Oil Seal From Tcv NBR FKM High Pressure Oil Seal Tcv Oil Seal

Trustworthiness is built through a proven track record of performance and reliability. Client testimonials and case studies from industries that rely on high-pressure rotary seals highlight instances of successful implementations, often involving complex and demanding applications. This credibility is further solidified by comprehensive customer service, including technical support from seasoned engineers and availability of detailed documentation and installation guides. Companies that prioritize transparency in communication, with clear warranties and service policies, enhance their reputation for reliability. In selecting high-pressure rotary seals, companies must consider several factors to ensure optimal performance. Key considerations include the operational environment, the type of fluid being sealed, temperature ranges, and the anticipated lifespan of the seal. Collaboration with seal manufacturers during the selection process can provide insights into customized solutions that meet specific operational needs. In summary, the role of high-pressure rotary seals in modern industry cannot be understated. Through a combination of real-world experience, unparalleled expertise, authoritative innovation, and unwavering trustworthiness, these components continue to be indispensable in ensuring the safe and efficient operation of machinery in some of the most demanding environments on the planet.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories