2 月 . 15, 2025 12:20 Back to list

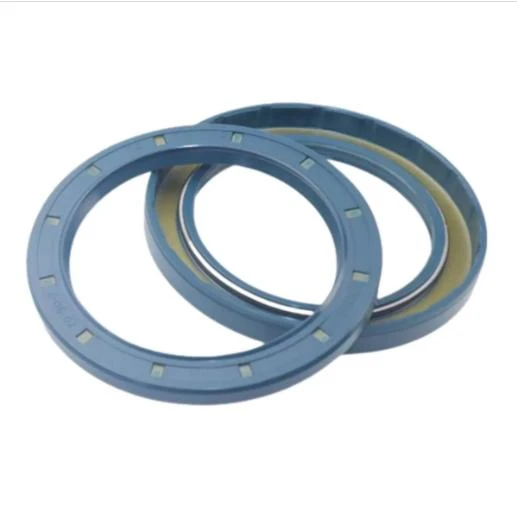

agricultural seals

Maintenance practices further contribute to the longevity and performance of gearbox seals. Regular inspections for signs of wear or leakage can prevent minor issues from turning into major failures. Check for any telltale signs such as dark, oily patches under the vehicle, which may suggest seal wear. Immediate attention to these signs can forestall more extensive and costly repairs. Expert guidance advises that gearbox lubrication levels are checked frequently. Insufficient lubrication often leads to increased friction and temperature, accelerating seal wear. Authoritativeness in the field of gearbox seals can be established by accessing published research and studies that benchmark various seal materials and designs. Peer-reviewed journals often provide in-depth comparisons of the performance of different seals under controlled conditions. Reading and understanding such studies can position a business as a knowledgeable resource in gearbox seal technology. Trustworthiness is built through delivering reliable products and services consistently. Partnering with reputable manufacturers known for quality and innovation in seal technologies is recommended. Certifications, such as ISO quality certifications, further establish a manufacturer's commitment to producing trustworthy and reliable products. Furthermore, offering warranties and guarantees on gearbox seals can reassure customers of product reliability and foster long-term consumer trust. In summary, gearbox seals are integral to maintaining the integrity of transmission systems across multiple applications. Adequate knowledge of material properties, expert installation, rigorous maintenance, authoritative research, and trustworthy partnerships are essential to choosing and using gearbox seals effectively. By focusing on these aspects, businesses can offer high-quality solutions that enhance performance and reliability, translating to longer gearbox life and reduced downtime. A comprehensive understanding and approach ensure that the right gearbox seal is selected for every specific operational need, leading to ultimate customer satisfaction.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories