8 月 . 29, 2024 03:22 Back to list

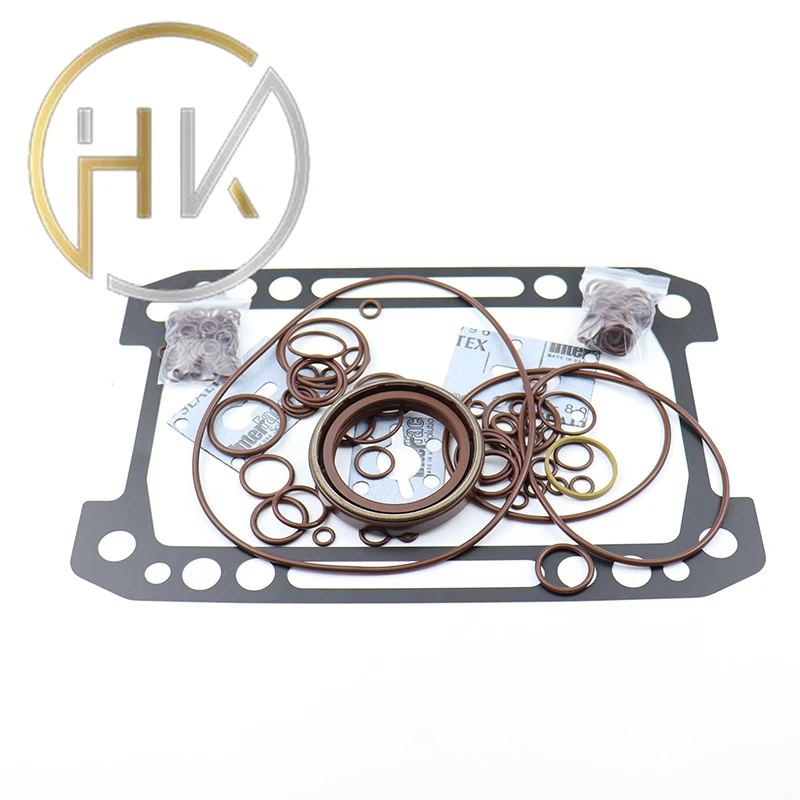

Gear Pump Seal Kit - High Quality Replacement Parts

Understanding Gear Pump Seal Kits Essential Components for Effective Pump Operation

Gear pumps are widely used in various industrial applications due to their reliable performance and ability to handle a variety of fluids. However, like any mechanical device, they require regular maintenance to ensure optimal operation. One critical component that often needs attention is the sealing system, which helps maintain efficiency and prevents leaks. This is where gear pump seal kits come into play.

A gear pump seal kit contains all the necessary components designed to replace worn or damaged seals in a gear pump

. These kits typically include various types of seals, gaskets, O-rings, and sometimes even additional components such as bearing assemblies or snap rings. The variety of materials used in these kits, such as rubber, PTFE (Teflon), or metal, caters to different applications, ensuring compatibility with the fluids being pumped and the operating conditions.The importance of a proper seal cannot be overstated. A compromised seal can lead to leaks, resulting in not only product loss and increased operational costs but also potential environmental hazards. In industries like oil and gas, chemicals, and food processing, maintaining fluid integrity is crucial. Therefore, using a high-quality seal kit that matches the specifications of the gear pump is essential.

gear pump seal kit

When selecting a gear pump seal kit, factors such as the type of fluid being pumped, temperature ranges, and pressure ratings should be considered. For example, when pumping abrasive liquids, a seal made from a more durable material may be necessary to withstand wear and tear. Similarly, high-temperature applications may require heat-resistant materials to prevent seal degradation.

Installation of a gear pump seal kit should be approached with care. Proper cleaning of the pump housing and components is vital before installation to remove any debris or old seal remnants. Additionally, it is crucial to follow manufacturer guidelines for torque specifications and sealing procedures to ensure a successful fit and prevent future leaks.

In conclusion, gear pump seal kits are indispensable for maintaining the integrity and efficiency of gear pumps across various industries. Regular inspection and timely replacement of seals can significantly extend the life of the pump, enhance its performance, and reduce the risk of operational interruptions. Investing in a quality seal kit not only helps avoid costly repairs but also contributes to a safer and more efficient working environment.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories