10 月 . 06, 2024 07:03 Back to list

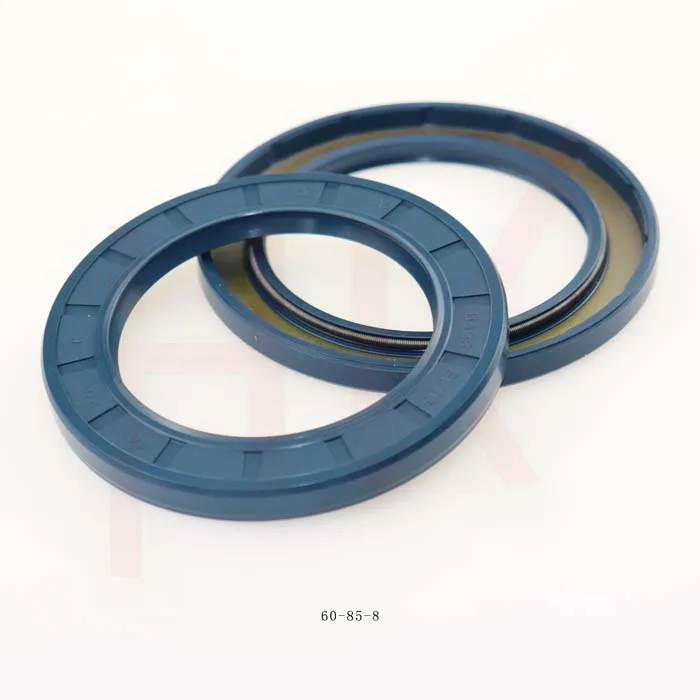

forklift hydraulic cylinder seals

Understanding Forklift Hydraulic Cylinder Seals

Forklifts are essential machinery in various industries, providing the lifting and moving power necessary to handle goods efficiently. A critical component of forklifts is the hydraulic system, which relies on hydraulic cylinders to enable movement and lifting operations. Among these components, hydraulic cylinder seals play a vital role in ensuring the functionality and safety of the entire system. This article delves into the significance of hydraulic cylinder seals in forklifts, their types, functions, and maintenance tips to ensure long-lasting performance.

The Importance of Hydraulic Cylinder Seals

Hydraulic cylinder seals are designed to prevent hydraulic fluid from leaking out of the cylinder while also keeping contaminants from entering the system. The integrity of these seals directly impacts the efficiency and safety of the forklift's operations. Leaks can lead to reduced operational pressure, which translates to lower lifting capacity and can compromise safety during operations. Moreover, contamination in hydraulic fluid can cause wear and tear on components, leading to costly repairs and downtime.

Effective sealing is crucial because hydraulic systems operate under high pressure. Therefore, the seals must be capable of withstanding these pressures without degrading over time. Properly functioning seals not only enhance the performance of the forklift but also contribute to the longevity of the hydraulic system and the machine as a whole.

Types of Hydraulic Cylinder Seals

There are various types of hydraulic cylinder seals, each designed for specific applications and conditions. The primary types include

1. Rod Seals These seals are positioned at the rod end of the cylinder. Their main job is to prevent hydraulic fluid from leaking out of the cylinder as the rod moves in and out. Rod seals must withstand dynamic movement and high pressure, making their material and design critical for performance.

2. Piston Seals Located inside the cylinder, piston seals prevent fluid from escaping the chamber as the piston moves to perform lifting or lowering actions. Like rod seals, piston seals must also endure extreme pressure and provide a tight seal to ensure efficient operation.

3. Backing Rings Often used in conjunction with piston and rod seals, backing rings help prevent extrusion and provide additional support to the sealing mechanism. They are essential for maintaining the seal's integrity under high pressure.

forklift hydraulic cylinder seals

4. Guides While not seals in the traditional sense, guide rings are essential components that help to stabilize the movement of the cylinder rod and reduce wear on other seals. They ensure that the rod remains aligned within the cylinder, preventing undue stress on the seals themselves.

Maintenance and Care

To ensure optimal performance and longevity of hydraulic cylinder seals in forklifts, regular maintenance is essential. Here are some tips to maintain hydraulic seals effectively

- Regular Inspections Conduct routine checks for any signs of leakage around seals. Early detection of leaks can prevent more severe issues down the line.

- Clean the Area Before performing any maintenance, ensure the surrounding area is clean. Contaminants can compromise the seals if they enter the hydraulic system during repairs.

- Monitor Fluid Levels Keeping an eye on hydraulic fluid levels can help address potential leaks before they become serious issues.

- Use Quality Fluids Always use recommended hydraulic fluids that meet the specifications set by the forklift manufacturer. Low-quality fluids can degrade seals prematurely.

- Replace Worn Seals Promptly If seals show signs of wear or damage, replace them immediately to prevent further damage to the hydraulic system.

Conclusion

Hydraulic cylinder seals are vital components of forklift hydraulic systems, ensuring efficient operation and safety. Understanding their types, functions, and the importance of regular maintenance can help forklift operators and maintenance teams keep their equipment in optimal condition. By prioritizing the health of hydraulic cylinder seals, businesses can enhance forklift performance, reduce downtime, and ultimately save on costly repairs. Investing time and resources in maintaining these crucial components will lead to smoother operation, increased productivity, and a safer workplace environment.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories