10 月 . 22, 2024 01:18 Back to list

Exploring the Advantages of Felt Wiper Seals in Various Applications

Exploring Felt Wiper Seals Function, Benefits, and Applications

Felt wiper seals are an essential component in various mechanical systems, providing a reliable solution for dust, dirt, and moisture control. With their unique blend of material composition and functional design, these seals play a critical role in enhancing the longevity and performance of machinery. This article will delve into the characteristics, advantages, and applications of felt wiper seals, shedding light on their importance in numerous industries.

What are Felt Wiper Seals?

Felt wiper seals are typically made from compressed felt material, which can be composed of natural fibers like wool or synthetic fibers such as polyester. The felt is designed to create a tight seal between moving parts, effectively wiping away unwanted contaminants as these parts operate. The fibers in the felt material are resilient and absorb moisture, making them ideal for applications where exposure to dust, dirt, or water is prevalent.

Functionality of Felt Wiper Seals

The primary function of felt wiper seals is to prevent the entry of foreign particles into critical machinery components. This is crucial in systems such as hydraulic cylinders, linear guides, and automotive components, where contamination can lead to premature wear and increased maintenance costs. Felt wiper seals work by wiping the surface of the rod or shaft as it moves, ensuring a clean interface and reducing friction between parts.

In addition to debris wicking, these seals also provide a degree of moisture control. The absorbent nature of felt allows it to draw away excess moisture, protecting mechanical systems from rust and corrosion. This feature is particularly beneficial in environments where humidity levels are high or where components are frequently exposed to liquids.

Advantages of Using Felt Wiper Seals

1. Cost-Effectiveness Felt wiper seals offer a budget-friendly solution compared to other sealing methods. The materials and manufacturing processes involved in producing felt seals are generally less expensive, making them an attractive option for many applications.

2. Versatility These seals can be customized to fit a wide range of applications, from heavy machinery to simple household items. They can be produced in different sizes and densities, ensuring that there is a felt wiper seal suitable for almost any need.

3. Maintenance Reduction By effectively keeping contaminants out, felt wiper seals can significantly reduce maintenance requirements. Machinery equipped with these seals often has extended service intervals, which translates to lower operational costs.

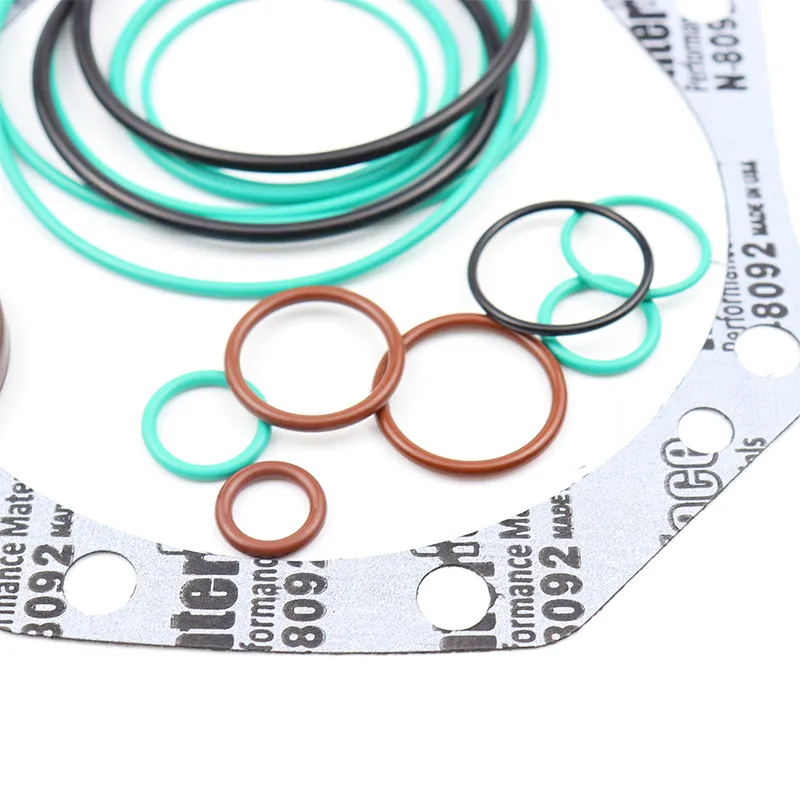

felt wiper seals

4. Resistance to Extreme Conditions Felt seals are resistant to a variety of conditions, including extreme temperatures and harsh chemicals. This durability makes them suitable for use in challenging environments, including automotive, aerospace, and industrial applications.

5. Eco-Friendliness With an increasing focus on sustainability, felt wiper seals made from natural fibers offer an environmentally responsible choice. They are biodegradable and can be sourced from renewable materials.

Applications of Felt Wiper Seals

The versatility of felt wiper seals allows them to be used in numerous industries

- Automotive In vehicles, felt wiper seals are commonly used in door locks, window guides, and other mechanisms to ensure smooth operation and protection against elements.

- Hydraulics Felt wiper seals are crucial in hydraulic systems, where they prevent contaminants from entering the cylinder and damaging internal components.

- Industrial Machinery In manufacturing settings, these seals are employed to protect moving parts in various machines, contributing to smoother operations and enhanced equipment reliability.

- Home Appliances Many household appliances utilize felt wiper seals to prevent the ingress of dust and dirt, thereby enhancing their lifespan and performance.

Conclusion

Felt wiper seals represent a vital innovation in mechanical sealing technology, providing a blend of protection, durability, and cost-effectiveness. As industries continue to prioritize efficiency and maintenance reduction, the role of felt wiper seals will only become more significant. Understanding the importance of these seals is crucial for engineers, manufacturers, and end-users alike, ensuring optimal performance of the equipment and longevity in their applications. Whether in heavy machinery or everyday appliances, felt wiper seals stand as a testament to the synergy between functionality and material science.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories