2 月 . 14, 2025 20:42 Back to list

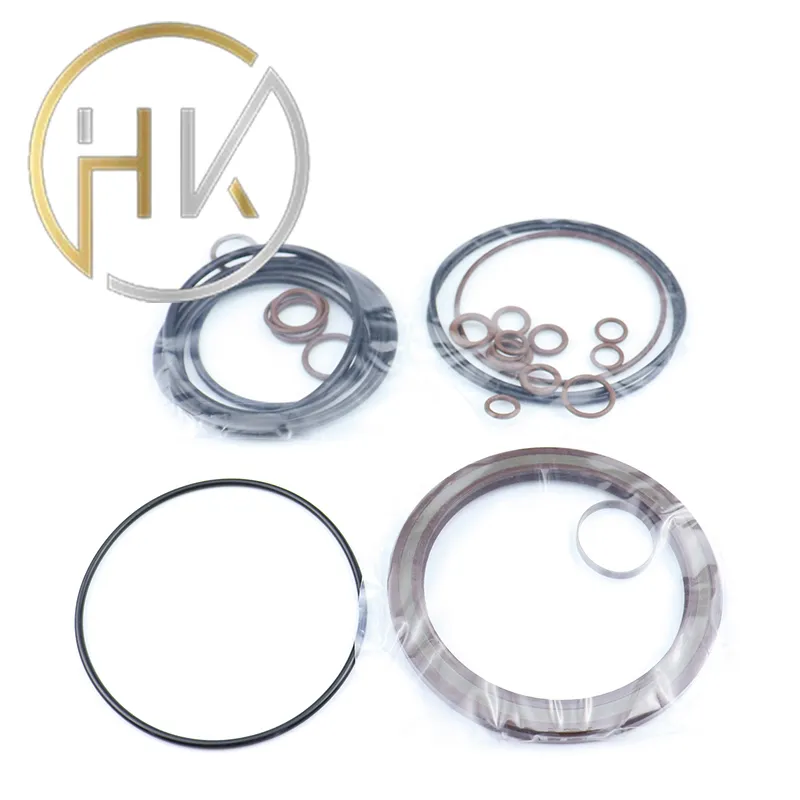

Standard High Pressure TCV Type Hydraulic Oil Seal

While companies manufacture generic seal kits, opting for ones crafted for specific excavator models ensures perfect fit and compatibility, thus enhancing operational efficacy. The Installation Experience What to be Prepared For Regularly replacing seals is crucial in pro-active maintenance strategies. Many experienced technicians stress the importance of a clean work environment during installation to avoid contaminating the seals with dirt or debris, which can lead to premature seal wear or damage. It’s beneficial to have a set of tools explicitly designed for seal installation to avoid unnecessary seal damage during fitting. After installation, running a series of hydraulic tests can verify that the seals perform appropriately under pressure, preventing premature operation errors. Ensuring Longevity Through Quality and Care Real-world experience suggests that high-quality seals expand the life expectancy of excavators considerably. Even the most well-crafted seals will eventually wear, but premium quality decreases frequency and severity of maintenance issues. Therefore, investing in reputable brands for seal kits can provide long-term savings by reducing downtime and extend the machine's life cycle. Building Trust Through Expertise Engaging with experts in the sale and installation of seal kits can provide companies with invaluable insights and recommendations, maximizing the efficiency and lifespan of their equipment. Reviews and case studies on trusted platforms or forums can serve as reliable sources for determining a vendor’s credibility. In conclusion, excavator seal kits are a critical investment for any operation involving heavy machinery. Their role in maintaining the hydraulic system's integrity cannot be overstressed. By understanding each component, selecting compatible materials, adopting meticulous installation practices, and investing in quality, businesses can minimize operational disruptions and maximize productivity. Elevated maintenance standards ultimately enhance the credibility and efficiency of construction operations, ensuring a sound return on investment over time.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories