10 月 . 22, 2024 01:45 Back to list

Excavator Seals for Optimal Performance and Longevity in Heavy Machinery Operations

Understanding Excavator Seals Importance, Types, and Maintenance

Excavators are pivotal machinery in the construction and mining industries, prized for their versatility and efficiency. A crucial element of their functionality is the myriad of seals, which serve as essential components in the hydraulic systems that drive their operation. This article explores the importance, types, and maintenance of excavator seals, emphasizing their role in ensuring optimal performance and longevity of the machinery.

The Importance of Excavator Seals

Excavator seals are crucial for preventing the leakage of hydraulic fluids. Hydraulic systems rely on pressurized fluids to operate various functions, including the movement of the boom, arm, and bucket. If there’s a failure in any of the seals, it can lead to fluid leaks, resulting in reduced efficiency and performance. Moreover, leaking hydraulic fluid can pose environmental hazards and increase operational costs due to wasted resources and the potential for more extensive repairs.

Seals also protect against contamination. Dust, dirt, and other foreign particles can easily infiltrate a hydraulic system, which can cause wear and tear on the internal components. High-quality seals create a barrier, ensuring that only clean fluid circulates within the system. This is vital for maintaining the overall health of the excavator, as contaminants can lead to premature failures and costly down-time.

Types of Excavator Seals

Excavator seals can be categorized into several types, each designed for specific functions and conditions

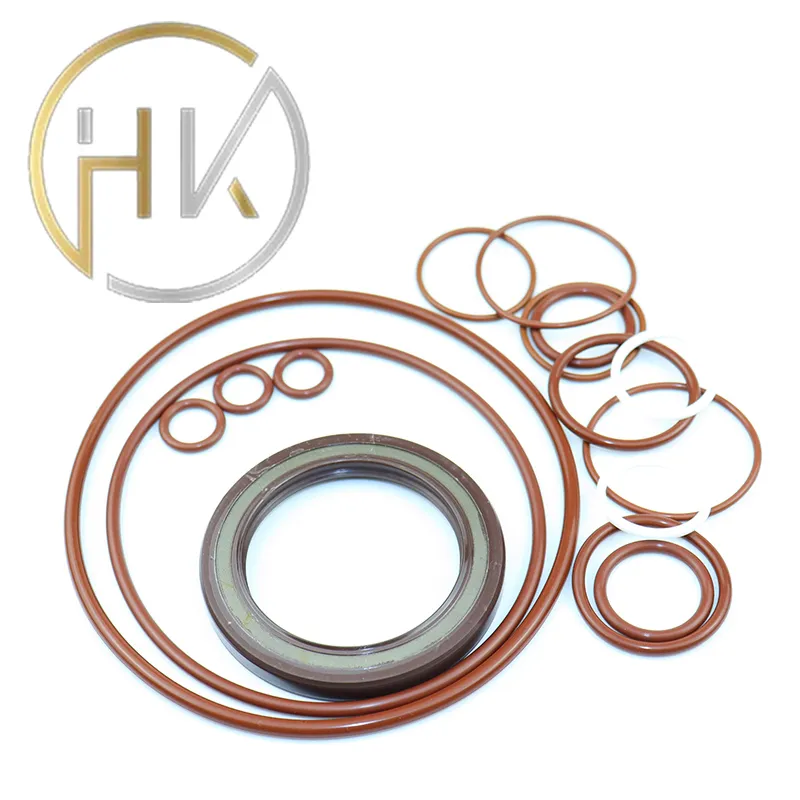

1. O-Rings These are circular seals that provide airtight seals in joints and connections. They are commonly used in various hydraulic systems due to their simplicity and effectiveness.

2. Rod Seals As the name suggests, rod seals are utilized to prevent fluid leakage around the hydraulic rods. They are essential for maintaining pressure and ensuring smooth operation of the cylinders.

3. Piston Seals Found in hydraulic cylinders, piston seals are designed to prevent fluid from leaking past the piston, maintaining the necessary pressure for lifting and digging activities.

4. Wear Rings These components are designed to reduce the friction between moving parts, protecting seals from damage caused by abrasive materials.

excavator seal

5. Dust Seals These seals prevent dirt and debris from entering the hydraulic system. Positioned at the outer part of the cylinders, they act as the first line of defense against contamination.

Maintenance of Excavator Seals

Proper maintenance of excavator seals is crucial to ensure the efficiency and longevity of the machinery. Here are some essential maintenance tips

1. Regular Inspection Operators should routinely inspect seals for signs of wear or damage. Routine visual inspections can help identify issues before they lead to significant problems.

2. Clean Environment Keeping the excavator clean and free from dust and debris is vital. Regularly cleaning around the hydraulic cylinders can prevent contaminants from being drawn into the seals.

3. Correct Installation When replacing seals, it’s essential to ensure they are installed correctly. Improper installation can lead to premature failure. Always refer to the manufacturer’s specifications and guidelines.

4. Monitor Fluid Levels Regular checks of hydraulic fluid levels are necessary. Low fluid levels can increase the risk of seal damage and system failure.

5. Use Quality Seals Investing in high-quality seals that are designed for the specific model and working conditions of the excavator can significantly reduce the chances of seal failure.

Conclusion

Excavator seals play a vital role in the performance and longevity of hydraulic systems within these powerful machines. Understanding the types of seals available, their importance, and how to maintain them is essential for operators and owners alike. By prioritizing seal maintenance and quality, one can ensure the efficient operation of excavators, thereby safeguarding an investment that is key to successful construction and mining operations. Proper care and attention to seals not only enhance machinery performance but also contribute to a safer and more environmentally friendly workplace.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories