10 月 . 12, 2024 20:08 Back to list

excavator boom cylinder seal replacement

Excavator Boom Cylinder Seal Replacement A Comprehensive Guide

Excavators are robust machines created for the toughest jobs on construction sites, including digging, lifting, and carrying. One of their most critical components is the boom cylinder, which helps to control the movement of the boom arm. Over time, seals within the boom cylinder can wear down or get damaged, leading to leaks and reduced efficiency. Regular maintenance, including seal replacement, is essential to ensure the proper functioning of your excavator. This guide will walk you through the importance of seal replacement, signs that indicate it's time for a replacement, and how to perform the task effectively.

Importance of Seal Replacement

The hydraulic system of an excavator is responsible for operating various functions, including the boom's movement. Seals are designed to prevent hydraulic oil from leaking outside the system and ensure that pressure is maintained. When seals fail, it can lead to several issues

1. Reduced Efficiency Leaking hydraulic fluid means that the excavator cannot generate the force required for optimal operation, resulting in decreased performance.

2. Increased Wear and Tear When the hydraulic system is compromised, it puts additional strain on other components, which may lead to premature wear and additional repairs.

3. Environmental Impact Hydraulic fluid leaks pose an environmental hazard. Oil spills can contaminate soil and water, leading to strict regulatory consequences and fines for construction companies.

4. Increased Operating Costs Ongoing leaks lead to the need for more frequent hydraulic fluid refills, increasing operating costs significantly over time.

Signs of Worn Seals

Identifying when your boom cylinder seals need replacement can save you from serious downtime and costly repairs

- Oil Leaks The most obvious sign is visible hydraulic fluid leaks around the boom cylinder. If you see oil dripping or pooling under your excavator, it's time to investigate.

- Decreased Power If the boom lift is slow or unresponsive, it may indicate that the hydraulic pressure is inadequate due to seal failure.

- Excessive Noise Any hissing or popping sounds when the boom is in operation could signal a problem within the hydraulic system, often related to damaged seals

.excavator boom cylinder seal replacement

How to Replace Boom Cylinder Seals

Replacing boom cylinder seals is a task that requires attention to detail and the right tools. Follow these steps for effective seal replacement

1. Safety First Ensure the excavator is on level ground and securely parked. Disconnect the battery and relieve hydraulic pressure by cycling the boom several times.

2. Remove the Boom Cylinder Carefully detach the boom cylinder from the excavator, following manufacturer guidelines. Use appropriate lifting tools and follow safety protocols.

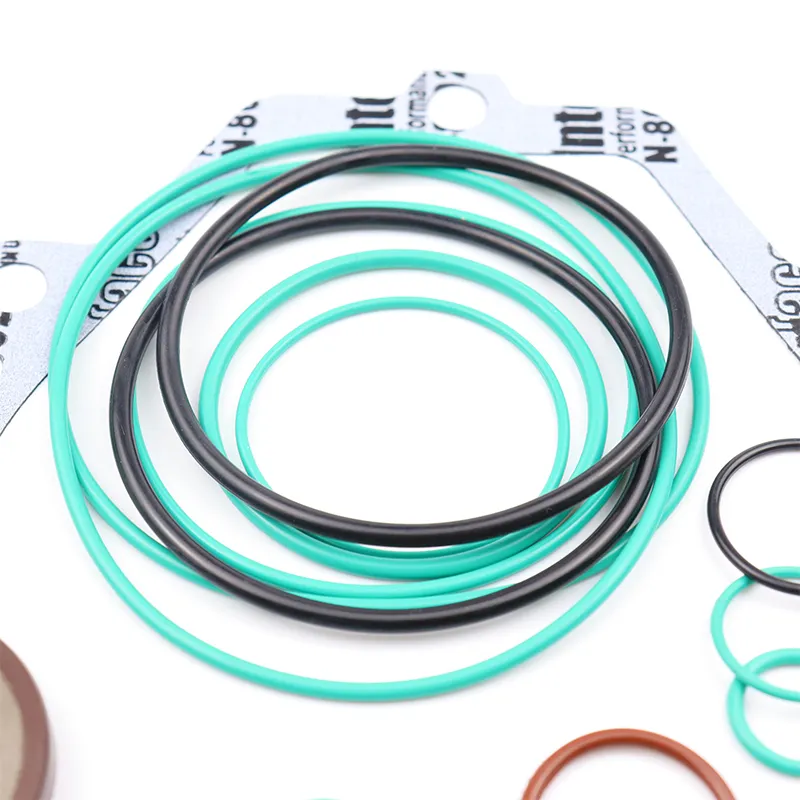

3. Disassemble the Cylinder Remove end caps and carefully slide out the old seals. Note the order and orientation of seals for accurate reassembly.

4. Clean the Components Inspect the cylinder for any scratches or damage that could affect its function. Clean all parts thoroughly with a soft cloth and an appropriate solvent.

5. Install New Seals Lubricate the new seals with hydraulic oil for easy installation. Carefully fit them into their respective grooves and ensure they are seated properly.

6. Reassemble the Cylinder Once the new seals are in place, reassemble the boom cylinder following the reverse order of disassembly.

7. Reattach the Cylinder Reinstall the boom cylinder onto the excavator, ensuring all connections are secure.

8. Test the System Reconnect the battery and test the hydraulic system for leaks. Cycle the boom through its full range of motion to ensure proper operation.

Conclusion

Regular maintenance, including timely replacement of boom cylinder seals, is vital for maintaining the performance and longevity of your excavator. By recognizing the signs of seal wear and knowing how to replace them, you can ensure optimal operation and prevent costly repairs down the line. Always refer to the manufacturer's manual for specific instructions and safety precautions, and when in doubt, consult with a professional mechanic. Maintaining your excavator not only protects your investment but also enhances productivity on the job site.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories