2 月 . 20, 2025 01:30 Back to list

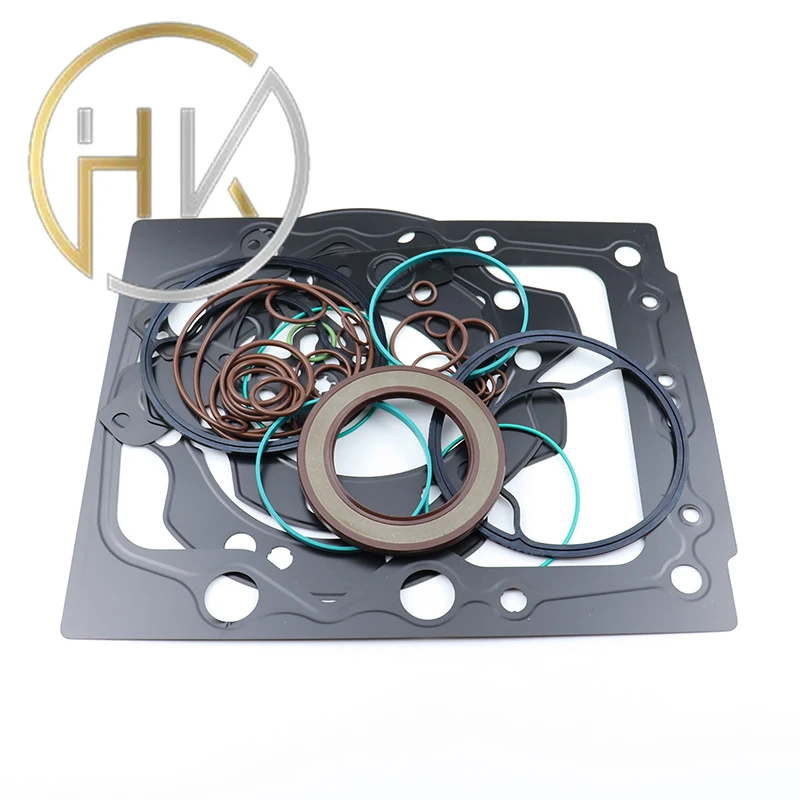

engine hoist hydraulic cylinder rebuild kit

Next comes the replacement of seals and o-rings, which are paramount in preventing oil leaks and maintaining pressure. This step demands a steady hand and a principle of precision; incorrect seal placement can jeopardize the entire cylinder's operation. Lubricate new seals with a compatible hydraulic oil to enhance durability and performance. Reassemble the cylinder, reversing the disassembly methods. Ensure each component fits snugly, eliminating the possibility of leaks or pressure loss. Changing seals and gaskets, while seemingly minor, require the profound experience of an expert, as each seal type—V-ring, O-ring, backup rings—has a specific application direction and orientation. Utilize a torque wrench to secure all fastenings to the manufacturer's specified tolerance. Bleeding the system is the final and critical step of the rebuild process. This involves filling the cylinder with the specified hydraulic oil and systematically expelling air pockets from the system to ensure seamless operation. The importance of accuracy and steadiness is stressed as even the tiniest air bubble can impair hydraulic efficiency. Trust in your capabilities amplifies with each successful rebuild, reinforcing the authoritativeness required to tackle complex maintenance challenges. Credibility builds as you abide by industry best practices, use quality kits, and apply seasoned techniques in every project. A rebuilt engine hoist hydraulic cylinder, when done correctly, is a testament to the synergy of expertise and comprehensive product understanding. This not only extends the hoist's operational longevity but also enhances reliability and performance. Embarking on this task might seem daunting at first, but the dividend it pays in terms of knowledge and mechanical efficiency makes it an invaluable endeavor for professionals and enthusiasts alike.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories