1 月 . 22, 2025 02:11 Back to list

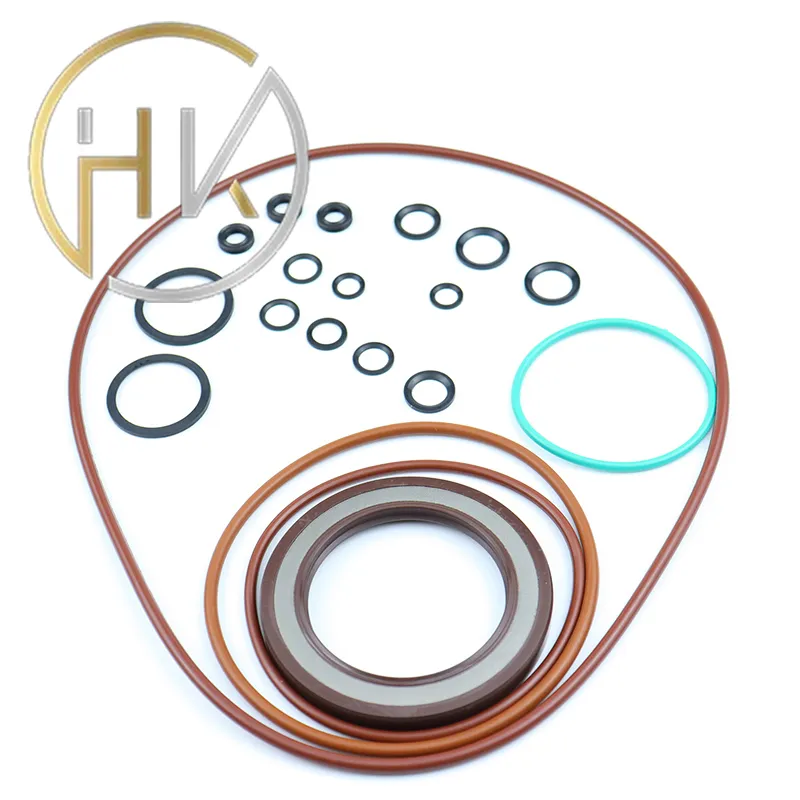

wiper seals

Furthermore, the installation and maintenance of dust wiper seals demand expertise. Improper installation can negate the benefits of even the highest quality seals. This is where the skills and experience of a seasoned professional become indispensable. Regular inspection and maintenance also play a role in ensuring the seal's longevity. Technicians should check for signs of wear, cracks, or any deformation regularly, replacing them as necessary to keep the machinery in peak condition. In understanding the broader implications of choosing and maintaining effective dust wiper seals, trust becomes a foundational aspect. Working with manufacturers and suppliers who prioritize quality and possess substantial expertise in seal technologies is paramount. Not merely sellers, but partners in ensuring that your operations run smoothly, efficiently, and without interruption. Investing in an authoritative voice in the seal industry guarantees that you are attaining seals crafted with the latest technological advancements and insights from extensive research and development. These are products born from a lineage of engineering excellence, committed to safeguarding machinery in ways that extend beyond mere functionality. In conclusion, the dust wiper seal is more than a component; it's a protector of investment and a testament to the diligent maintenance that high-performing systems require. For machinery to run seamlessly, end-users must acknowledge the significance of these seals, entrust the expertise of skilled professionals, and ensure a sustained partnership with industry innovators. Such foresight and commitment to quality can lead to optimal performance and operational efficacy.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories