12 月 . 03, 2024 17:43 Back to list

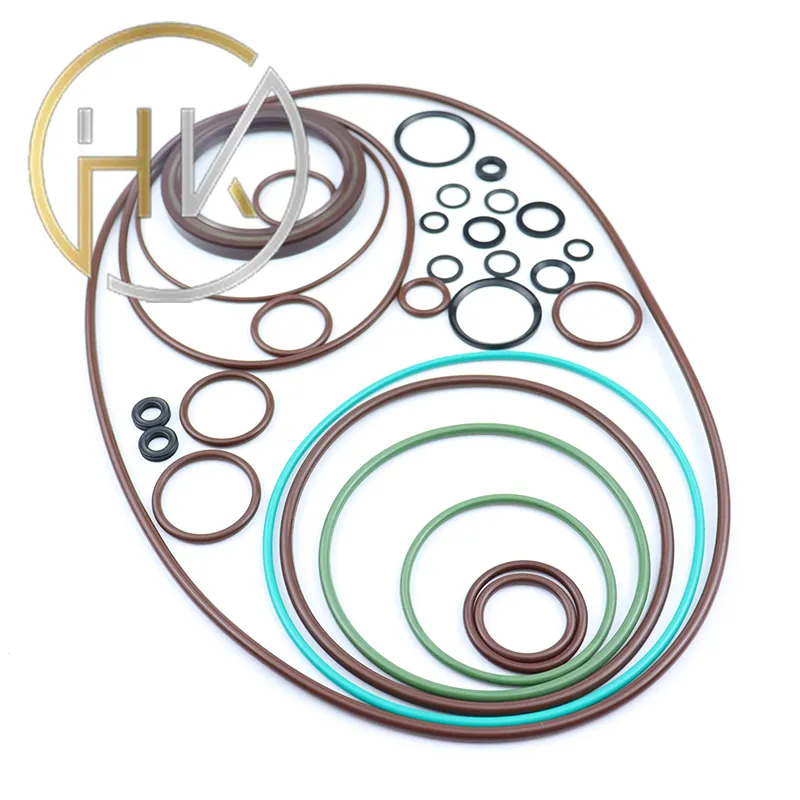

dust wiper seal

Understanding Dust Wiper Seals

Dust wiper seals play a crucial role in the maintenance and longevity of various machinery, particularly in heavy equipment, manufacturing processes, and automotive applications. These seals are designed to prevent contaminants, such as dust, dirt, and moisture, from infiltrating critical components, ensuring that machinery operates smoothly and efficiently. This article explores the importance, types, and applications of dust wiper seals, as well as best practices for their maintenance.

What are Dust Wiper Seals?

Dust wiper seals are protective barriers located at the entrance of moving parts, particularly hydraulic cylinders, bearings, and other rotating or sliding assemblies. Their primary function is to wipe away contaminants that may threaten the integrity and performance of these components. By creating a physical barrier, dust wiper seals help maintain the cleanliness of lubrication areas and prevent wear and damage caused by abrasive materials.

Importance of Dust Wiper Seals

1. Contamination Protection One of the most significant advantages of dust wiper seals is their ability to protect against external contamination. Machinery operating in harsh environments, such as construction sites or manufacturing plants, is particularly vulnerable to dirt and dust. By keeping these elements at bay, dust wiper seals prolong the service life of vital components.

2. Reduced Maintenance Costs By preventing contaminants from entering machinery, dust wiper seals can significantly reduce the frequency and cost of maintenance and repairs. Well-maintained equipment often lasts longer, thereby providing a better return on investment.

3. Enhanced Operational Efficiency Clean machinery operates more efficiently. Contaminants can cause mechanical failures that lead to downtime. By utilizing dust wiper seals, operators can ensure smoother operations and minimize the risk of unplanned shutdowns.

4. Improved Safety In sectors like construction and manufacturing, equipment failure can pose serious safety risks to workers. Dust wiper seals contribute to safer working environments by maintaining the integrity of machinery and preventing accidents related to mechanical breakdowns.

Types of Dust Wiper Seals

Dust wiper seals come in various designs and materials, each tailored to specific applications. Common types include

dust wiper seal

1. Single Lip Seals These seals feature a single wiping lip that makes contact with the shaft or rod to remove contamination. They are often made of rubber or polymer materials.

2. Double Lip Seals Featuring two lips, these seals provide enhanced protection by creating an additional barrier against dust and dirt while also allowing for lubrication retention.

3. Metal Wiper Seals For applications involving high pressure or extreme conditions, metal wiper seals offer a robust solution. They are less common but are essential in specific industrial settings.

4. Rotary Wiper Seals Designed for rotating shafts, these wiper seals help keep contaminants at bay while maintaining the necessary fluid film for lubrication.

Applications

Dust wiper seals are prevalent across various industries, including

- Construction Heavy machinery such as excavators and bulldozers rely on dust wiper seals to guard against the harsh environmental conditions typically found on job sites. - Automotive Vehicles use dust wiper seals in suspension systems and transmissions to protect vital components. - Manufacturing Equipment such as conveyors and CNC machines benefit from dust wiper seals to ensure smooth operations and minimal downtime.

Maintenance and Best Practices

To ensure optimal performance of dust wiper seals, regular inspections and maintenance are crucial. Operators should periodically check seals for signs of wear, cracking, or other damage. Depending on the environment and application, it may be necessary to clean or replace seals as part of routine maintenance schedules.

In conclusion, dust wiper seals are indispensable in safeguarding equipment from contaminants, reducing maintenance costs, and enhancing overall operational efficiency. By understanding their importance and implementing best practices for maintenance, industries can maximize the performance and lifespan of their machinery, promoting a safer, more productive work environment.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories