10 月 . 11, 2024 10:26 Back to list

Comparison of Dust Seals and Oil Seals for Enhanced Equipment Protection

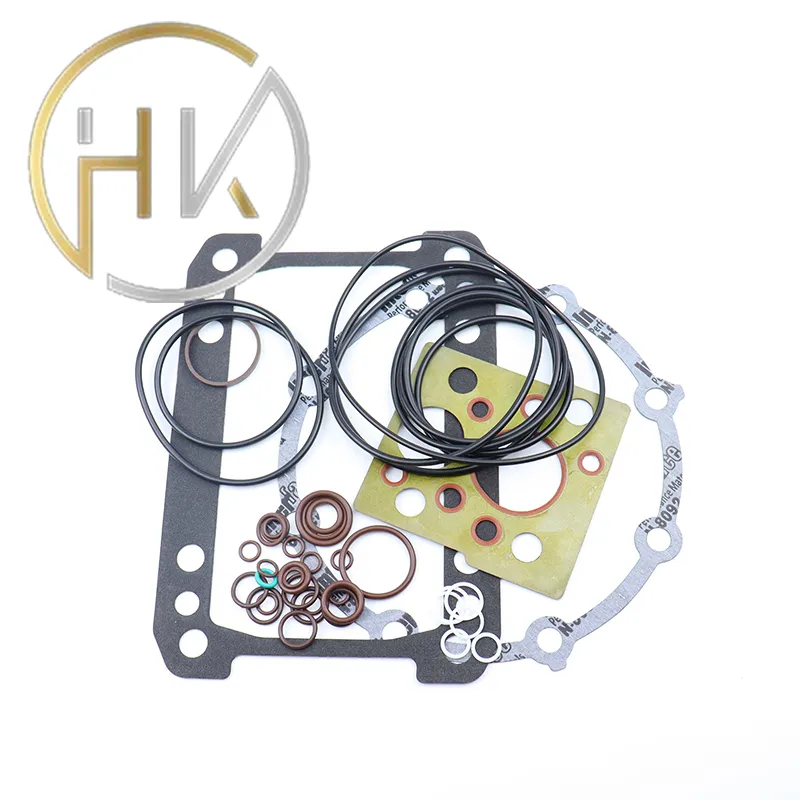

Dust Seal vs. Oil Seal A Detailed Comparison

When it comes to mechanical components, seals play an essential role in maintaining the integrity and functionality of machinery. Among the various types of seals, dust seals and oil seals serve different purposes and are designed to address specific challenges. Understanding the distinctions between these two types of seals is crucial for selecting the right one for your application.

What is a Dust Seal?

A dust seal, also known as a dust cover, is designed to protect moving parts from dust, dirt, and other environmental contaminants. These seals are typically used in applications where components are exposed to harsh conditions, such as in off-road vehicles, construction equipment, and industrial machinery. Dust seals are usually made from rubber, plastic, or other resilient materials and are intended to provide a tight fit that prevents debris from entering critical areas.

Functionality of Dust Seals

1. Contaminant Protection Dust seals primarily act as barriers against particulate matter. They prevent dust, dirt, and other contaminants from entering the system, which could lead to wear and tear or failure of internal components. 2. Maintenance of Cleanliness By keeping moving parts free of grime, dust seals help maintain the cleanliness of the operating environment, which can enhance the overall performance and longevity of the machinery.

3. Simple Installation Dust seals are generally easier to install due to their straightforward design. They do not require complex mechanisms and can often be fitted with minimal tools.

What is an Oil Seal?

On the other hand, an oil seal, also known as a rotary shaft seal, is designed to retain lubricants, such as oil or grease, within machinery while preventing leakage. Oil seals are crucial in various applications, including automotive engines, gearboxes, and hydraulic systems. These seals are made from materials that can withstand the chemical properties of the lubricants and the temperature variations within the machinery.

Functionality of Oil Seals

dust seal vs oil seal

1. Fluid Retention The primary role of an oil seal is to keep lubricants contained within a compartment, ensuring smooth operation of moving parts by reducing friction and preventing overheating.

2. Leak Prevention Oil seals are designed to prevent leakage of the lubricant, which is essential for maintaining pressure within the system and preventing environmental contamination.

3. Durability Under Pressure Oil seals are usually built to endure higher pressure and temperature conditions compared to dust seals. This makes them suitable for applications where the machinery operates under extreme conditions.

Key Differences Between Dust Seals and Oil Seals

1. Primary Function The fundamental difference lies in their purpose; dust seals prevent contaminants from entering, while oil seals retain lubricants and prevent leakage.

2. Material Composition While both dust seals and oil seals can be made from rubber or synthetic materials, oil seals are often constructed from more specialized compounds that can withstand heat, oil, and other chemical exposures.

3. Design Considerations Dust seals usually have a simple design that focuses on blocking particulate ingress, whereas oil seals must incorporate a more sophisticated design to create an effective barrier against fluid loss.

4. Application Areas Dust seals are commonly used in environments where dust and dirt are prevalent, such as in the automotive and construction fields. In contrast, oil seals are typically found in enclosed systems where lubricants are essential for operation, like in engines and hydraulic systems.

Conclusion

Choosing between a dust seal and an oil seal depends on the specific needs of your application. If your primary concern is protecting machinery from external contaminants, a dust seal is the way to go. Conversely, if you need to ensure that lubricants remain inside the machine and prevent leaks, an oil seal is necessary. Understanding the differences between these seals and their respective functionalities can help you make informed decisions, ultimately leading to better maintenance practices and longer equipment life. Always consider the environmental conditions and specific requirements of your machinery when selecting seals, as this will ensure optimal performance and reliability.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories