10 月 . 31, 2024 23:52 Back to list

Effective Dust Seal Solutions for Enhanced Protection and Longevity in Machinery

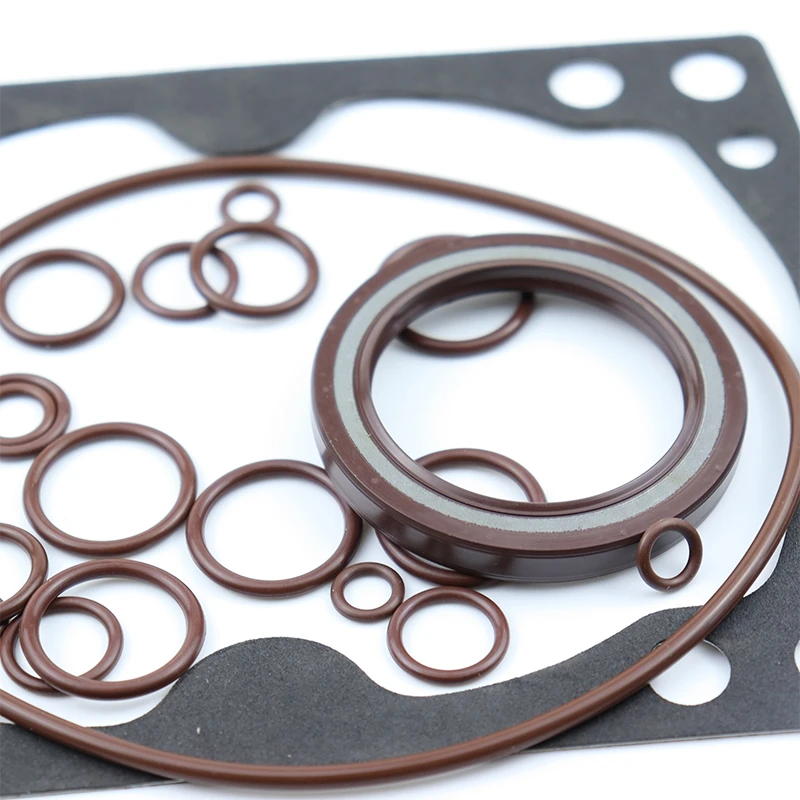

The Importance of Dust Seals in Machinery

Dust seals play a crucial role in the operation and longevity of various types of machinery and equipment. Their primary function is to prevent the ingress of dust, dirt, and other contaminants that could potentially harm sensitive components. In an era where precision and reliability are paramount, understanding the importance of dust seals is essential for anyone involved in maintenance and engineering.

Dust seals are typically made from durable materials like rubber or silicone, which provide an effective barrier against particulate matter. These materials are engineered to withstand various environmental conditions, including extreme temperatures and mechanical wear. The design of these seals can vary, but they commonly feature a lip that contacts the moving part, ensuring that dust and debris are kept at bay. Properly installed dust seals can significantly reduce the need for repairs and enhance the lifespan of mechanical systems.

In industrial settings, dust can be an insidious enemy. It penetrates machinery and can exacerbate wear on moving parts, leading to increased friction, overheating, and ultimately, failure. For industries such as manufacturing, construction, and agriculture, where machinery operates in dusty environments, the importance of effective dust sealing becomes even more pronounced. Regular maintenance checks should include inspections of dust seals to identify any signs of wear or damage. Prompt replacement of compromised seals can save significant costs in the long run and prevent catastrophic breakdowns.

dust seal

Moreover, the implications of neglecting dust seals extend beyond machinery performance. For example, in sectors such as food processing or pharmaceuticals, maintaining a dust-free environment is vital for product safety and compliance with regulatory standards. The presence of dust can lead to contamination, affecting product quality and posing health risks. Thus, the installation and maintenance of dust seals become not just a matter of equipment longevity, but also of safety and regulatory adherence.

Furthermore, advancements in technology have led to the development of more effective sealing solutions. Innovations such as self-adjusting seals or seals with embedded sensors for real-time monitoring are becoming more common. These technologies not only improve the efficiency of dust seals but also enhance the overall reliability of machinery. By integrating modern materials and designs, manufacturers can provide solutions that meet the increasing demands for sustainable and efficient operations.

In conclusion, dust seals are not mere components; they are fundamental to the reliability, safety, and efficiency of machinery across various industries. Understanding their function and importance emphasizes the need for regular inspection and maintenance practices. By investing in high-quality dust seals and prioritizing their upkeep, businesses can safeguard their equipment, enhance productivity, and ensure compliance with industry standards. As technology continues to evolve, the future of dust sealing solutions promises even greater innovations that will further protect and optimize machinery, cementing their place as an essential element in industrial operation.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories