1 月 . 21, 2025 03:24 Back to list

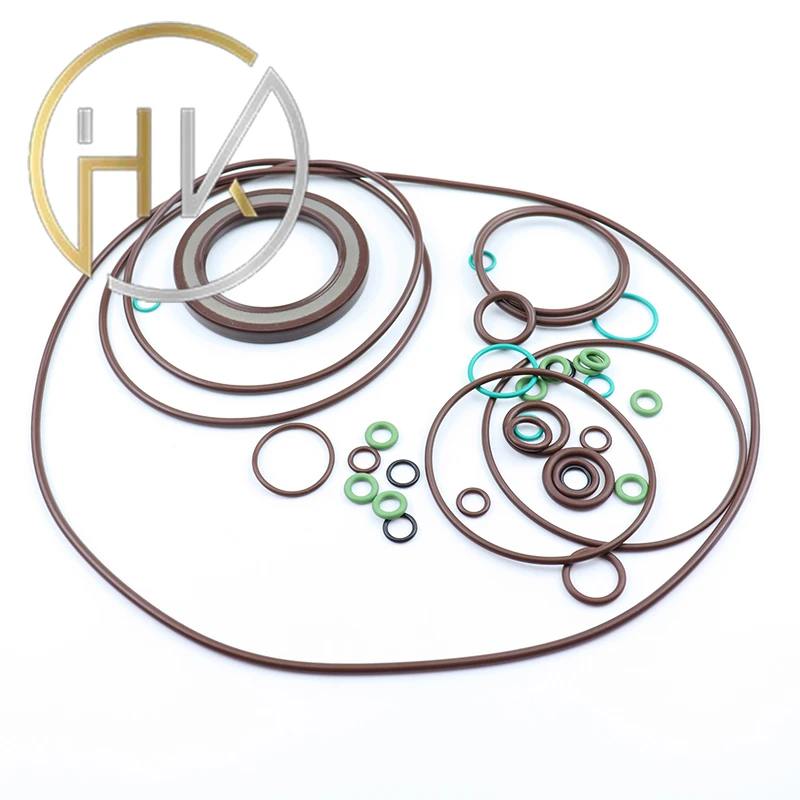

dust proof sealing

The value of dust proof sealing extends into the industrial sector, where machinery and equipment frequently operate in dust-laden environments. Industrial seals must provide high resistance to particles that could otherwise cause wear, contamination, or damage. The expertise required to develop these solutions involves a deep understanding of both the machinery and the operational environment. Professionals in this field apply their authoritative knowledge to assess the interaction between the sealing device and the equipment it protects, ensuring seamless performance and prolonged service life. Authorities in the field of dust proof sealing emphasize the importance of regular maintenance and audits to assure continued protective performance. Over time, environmental factors and mechanical wear can degrade seals, potentially compromising their effectiveness. An experienced professional conducts audits to identify potential vulnerabilities, allowing for proactive measures that prevent unforeseen breakdowns. This proactive approach builds trust with stakeholders who value reliability and continuous operation. A comprehensive approach to dust proof sealing involves integrating the latest technologies and innovations. Industry experts are constantly researching new material formulations and design techniques to enhance performance and create more effective sealing solutions. Adopting cutting-edge advancements, such as self-healing materials and intelligent sensors, elevates the sealing technology to a new level of sophistication, promising longer-lasting protection. In conclusion, dust proof sealing is a vital aspect of product design and functionality across various industries. Its effective implementation requires a blend of real-world experience, expert knowledge, and innovative thinking. Those who seek to develop or refine dust proof sealing solutions must engage with seasoned professionals who can provide authoritative guidance and trustworthy solutions. As a result, industries can achieve enhanced performance, reduced downtime, and increased confidence in their products' durability and reliability.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories