12 月 . 03, 2024 18:46 Back to list

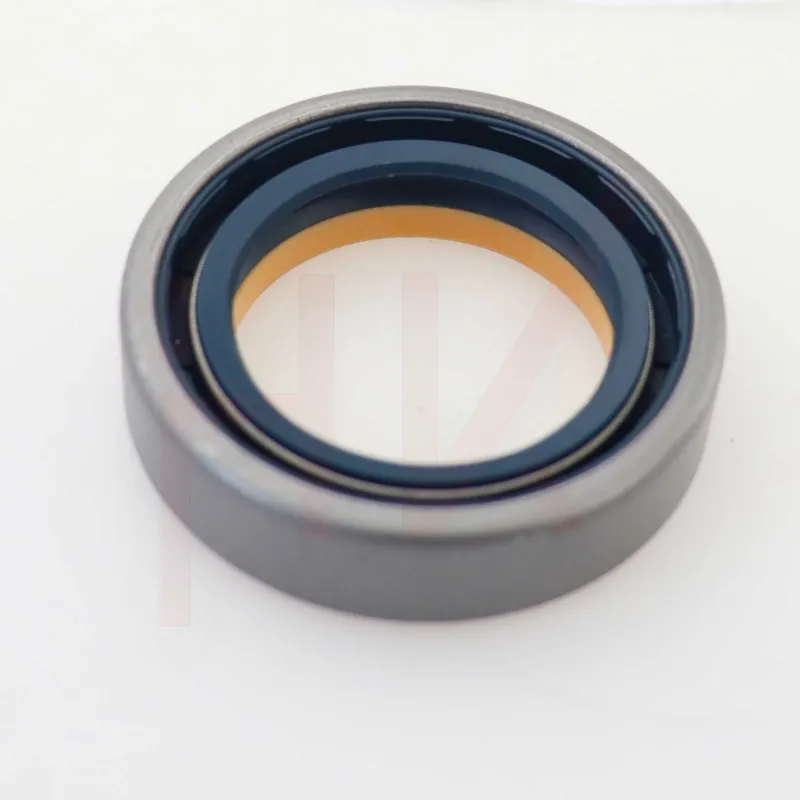

dust lip seal

Understanding Dust Lip Seals Importance and Applications

In various industrial applications, maintaining the integrity of machinery is crucial to ensure optimal performance and longevity. One of the components that plays a significant role in preserving the operational efficiency of machinery is the dust lip seal. Though often overlooked, the dust lip seal is vital in preventing contamination and protecting essential parts from wear and tear.

What is a Dust Lip Seal?

A dust lip seal is a type of mechanical seal designed to prevent dust, debris, and moisture from entering critical areas of machinery. Typically made of elastomeric materials like rubber or polyurethane, these seals feature a flexible lip that makes contact with the surface of the machinery. This contact creates a barrier, effectively keeping unwanted particles away from sensitive components such as bearings, gears, and hydraulic systems.

The design of the dust lip seal is critical to its functionality. The lip is engineered to create enough pressure against the surface while allowing for a slight tolerance to accommodate movements and vibrations. The successful operation of a dust lip seal relies on its ability to adapt to varying conditions while maintaining its sealing effectiveness.

Importance of Dust Lip Seals

1. Contamination Prevention The primary role of dust lip seals is to prevent contaminants from entering machinery. Dust, dirt, and various particles can cause significant damage to working components, resulting in failures that can be costly and time-consuming to rectify. By ensuring a barrier against these elements, dust lip seals contribute to the overall reliability of the equipment.

2. Extended Equipment Life Machinery faces harsh operating environments. The wear and tear caused by dirt and moisture can significantly accelerate the degradation of components. Dust lip seals help in maintaining a cleaner environment around critical parts, leading to extended equipment life and reduced maintenance costs.

3. Efficiency Maintenance Contaminated machinery can lead to inefficiencies such as increased friction, overheating, and energy consumption. By preventing contaminants from entering, dust lip seals help maintain optimal performance levels. This is particularly important in applications involving precision parts, where even a small amount of dirt can lead to malfunction.

4. Cost-Effectiveness The initial investment in quality dust lip seals can lead to substantial long-term savings. By reducing equipment failure rates and prolonging maintenance intervals, companies can save on repair costs and lost productivity. This makes dust lip seals not only a protective measure but also a strategic investment.

dust lip seal

Applications of Dust Lip Seals

Dust lip seals are widely used across various industries, showcasing their versatility and reliability. Here are some common applications

1. Automotive Industry In vehicles, dust lip seals are commonly employed in wheel bearings, shock absorbers, and drive shafts, protecting these components from harsh road conditions and debris.

2. Manufacturing Equipment Heavy machinery used in manufacturing often operates in environments filled with dust and particulate matter. Dust lip seals are essential in protecting hydraulic systems and moving parts within this equipment.

3. Agricultural Machinery Tractors and agricultural implements frequently encounter dirt and moisture. Dust lip seals provide necessary protection to critical machinery components from the rigors of agricultural environments.

4. Construction Equipment Equipment like excavators and bulldozers operates in demanding conditions. The use of dust lip seals ensures that the hydraulic cylinders and bearings remain protected from abrasive materials.

5. Electronics In some electronic applications, dust lip seals can be utilized to protect sensitive components from dust intrusion, enhancing the longevity and reliability of devices.

Conclusion

Dust lip seals are a crucial component in safeguarding machinery from the elements that can lead to inefficiency and failure. Their ability to protect against dust, debris, and moisture not only enhances the equipment's performance but also extends its operational lifespan. As industries continue to seek ways to increase efficiency and reduce costs, the importance of reliable sealing solutions, such as dust lip seals, cannot be overstated. Understanding their function and application can lead to better maintenance practices and improved machinery reliability across various sectors. By prioritizing effective sealing solutions, businesses can pave the way for enhanced productivity and reduced downtime in their operations.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories